Raptor Rapid Control Prototyping

Take control of your system development from the start without paying $10,000s for generic rapid prototyping hardware. Our embedded Model-Based Development (eMBD) platform, Raptor™, makes developing custom control software that cleanly integrates onto ruggedized hardware quick, easy, and affordable. Raptor™ provides the development speed of Rapid Control Prototyping systems that you may already know, coupled with controller hardware that is a fraction of the price typical with these systems.

The Raptor tool chain matches industry-standard software tools with off-the-shelf controller products, allowing you develop control software for complex electromechanical systems. Developers can easily create, compile, build, and flash the model onto ruggedized, off-the-shelf hardware without the hassle of manual programming.

Rapid Prototype Development

Get your prototype up and running quickly with the Raptor tool suite. Utilizing the graphical programming environment of MATLAB/Simulink, developers can quickly and easily develop software using multiple block libraries with numerous interface functionalities and configurable I/O capabilities. Our tools allow you to automatically build, test, and integrate prototype models, as well as make real-time calibration changes, without manual programming.

High Quality Controllers

Automatically integrate your controls software onto rugged, cost-efficient hardware built to endure the harshest of environments. New Eagle offers a variety of trusted ECUs that range in pin count, input, output, memory, and processor configuration, and are tailored to suit a variety of applications. With our ASIL capable, IP6k9k compliant controllers that can typically operate in temperatures ranging from -40C to +105C, our ECUs are built with the most rigid standards available. In addition, each Raptor enabled ECU ranges in pin count, I/O capabilities, and processor configuration to better suit a variety of applications while costing significantly less than typical prototyping hardware.

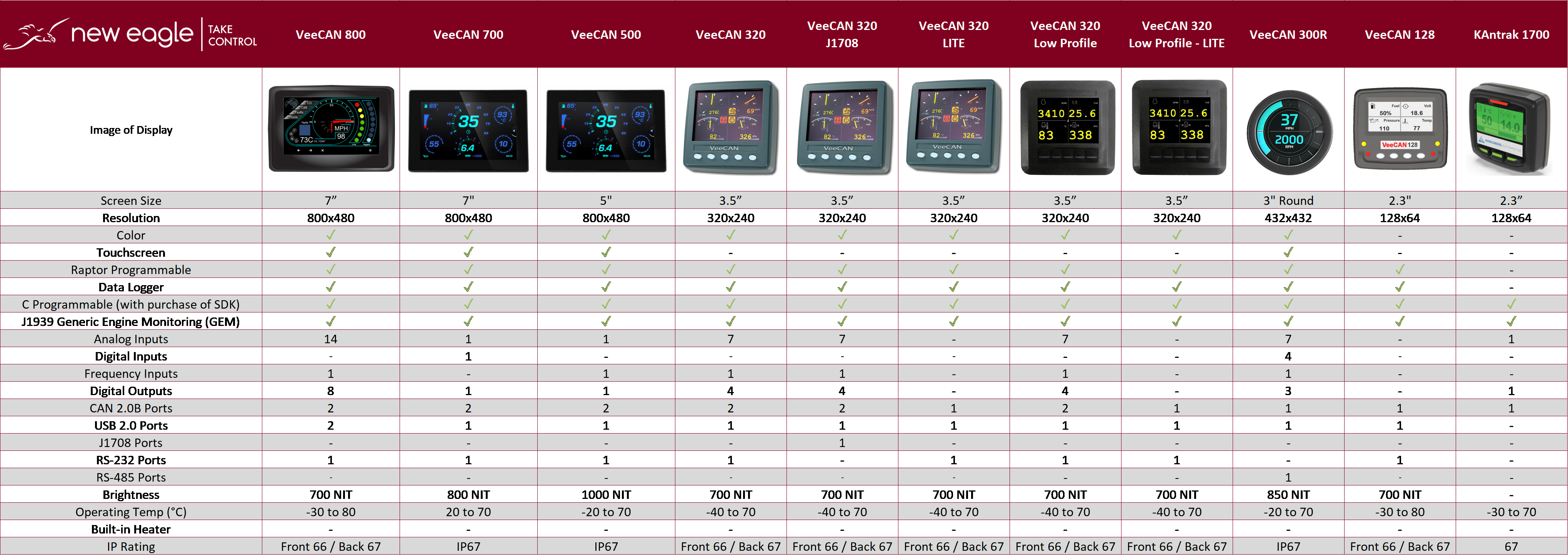

High Quality Displays

With fast development cycle times using model-based simulation, rapid-prototyping, controls development, and ruggedized, off-the-shelf hardware, developers can optimize their control system design in a cost efficient manner.