Alternative Fuel Vehicles: Difference between revisions

No edit summary |

|||

| (84 intermediate revisions by 8 users not shown) | |||

| Line 1: | Line 1: | ||

= Introduction = | = Introduction = | ||

New Eagle has experience in engine controls development for a range of alternative fuel applications. There is a push towards the use of alternative fuels in the transportation industry based on the reduced operating costs, decreased environmental impact and domestic availability. For consumption of alternative fuels to increase, infrastructure and vehicle solutions must be put in place. New Eagle is well placed to assist in supporting the need for vehicle solutions with low-volume product distribution and engineering support. New Eagle distributes high capability automotive controllers and engine control software, plus auxiliary displays, throttle bodies, injectors and other engine and vehicle components to companies producing alternative fuel solutions. In addition to hardware and software, New Eagle also provides engineering resources to support our customers in the development of the full range of alternative fuel systems and vehicles. This support can range from mechanical system integration through to complete engine control systems for all markets. | |||

=Alternative Fuel Components= | |||

New Eagle has an extensive supplier network to provide the best validated components at competitive prices. This offering includes a full set of components required for the design and assembly of alternative fuel vehicle systems. Please see our '''[[Engine Control]]''' page for more information on industrial parts and components, or use the "Products by Application" and "Products by Category" sections to search the wiki. | |||

=Alternative Fuel Systems= | |||

There is a range of applications which allows vehicles to operate on alternative fuels, and New Eagle has extensive experience on the most common examples of these: dedicated, bi-fuel and dual-fuel. | |||

*Dedicated systems will operate on only one fuel - for example conventional diesel and gasoline engines are typically dedicated fuel engines. These engines can then be converted to operate "dedicated" on DME (from diesel) and CHG or propane autogas (from gasoline). | |||

*Bi-fuel systems are designed to allow an engine to switch between a primary and a secondary alternative fuel during operation. Generally speaking, the engine can operate on either fuel at any time. Examples of this are bi-fuel gasoline/CNG and bi-fuel gasoline/propane autogas. | |||

*Dual-fuel systems allow an engine to operate on a blend of the primary and alternative fuel sources, but the primary fuel must always be present. Examples of this are dual-fuel diesel/CNG compression ignition engines being introduced in many larger engines. | |||

. | '''Notes: | ||

. | *The definitions for bi-fuel and dual-fuel are swapped across the industry. | ||

*For completeness, flex-fuel systems allow not just a switch between a primary and alternative fuel but also a blending of the two. | |||

New Eagle has experience with the development of most of these types of systems for alternative fuel vehicles. The New Eagle engineering team has experience with safety-critical system development, vehicle integration, communication protocol standards and diagnostics, and this expertise is integrated into our solutions. | |||

New Eagle has | |||

== Certified Dedicated Alternative Fuel Heavy-Duty Spark-Ignited Engine == | |||

[[File:LPG_engine_control.png|450px | right]] | |||

[[File:Gasengine.jpg|350px | right]] | |||

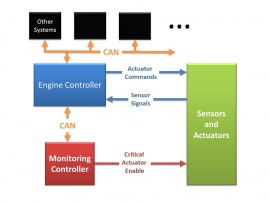

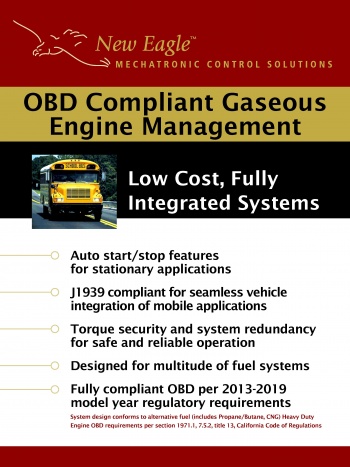

Powertrain Integration has developed an 8.0L, V8, naturally aspirated engine to operate on dedicated propane autogas fuel for various Freightliner truck and bus platforms. For this new engine configuration, New Eagle was chosen as the engine control system provider - supplying both the engine controller hardware and the full engine control model and strategy. The control system developed by New Eagle includes model-based torque estimation, torque limiters and arbitration as well as various OBD-specific physically based models. The controls system is designed to be safety critical and provides redundant monitoring of critical paths. This control system has been fully certified by CARB and U.S. EPA to meet 2013 on-highway standards. | |||

The developed Engine Control Software has the following features: | |||

*Pedal interpretation as torque requester | |||

*Cruise control | |||

*PTO control | |||

*Torque limiting functions | |||

*Torque arbitration (between pedal, cruise, PTO) | |||

*Open-loop fuel control | |||

*Close-loop fuel control | |||

*Airflow characterizations and dynamics | |||

*Idle control | |||

*Deceleration fuel cutoff and safety fuel cutoff | |||

*Ignition angle and energy characterization | |||

*Engine torque characterization | |||

** Forward path: friction and pumping losses, indicated engine torque to air charge characterization, modifiers for ignition retarding, temperature and pressure modifiers, equivalence ratio modifier, ignition angle offset request based on fast path torque, torque reserve request | |||

** Reverse path: frictional and pumping losses, air charge to torque characterization, modifiers for ignition retarding, equivalence ratio modifier, temperature and pressure modifiers, fuel cutoff | |||

** Slow path: throttle-based slow path torque delivers nominal torque plus torque reserve request | |||

** Fast path: spark-based fast path torque delivers transient torque requests from torque reserve | |||

*Modeled air charge | |||

*Engine state determination | |||

*Steady state determination | |||

*Modeled temperatures | |||

*Lambda | |||

*Accessory control | |||

*Throttle position control | |||

*HEGO heater control | |||

*Injector characterization | |||

*Ignition angle and energy characterization | |||

*Sensor rationalities for redundancy | |||

*Secondary microprocessor rationalities | |||

*OBDII Diagnostics | |||

*OBDII Major monitors | |||

**Fuel system monitor | |||

**Catalyst monitor | |||

**Catalyst temperature model | |||

**Engine coolant temperature monitor | |||

== | == Bi-Fuel Gasoline CNG or Propane Autogas Engines == | ||

[[File:BiFuelSystemDiagram.png|400px |left]] | |||

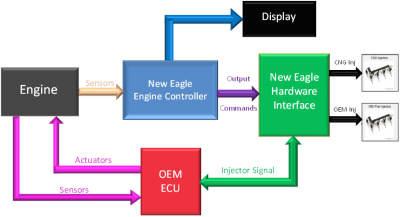

New Eagle has verified a bi-fuel system design which utilizes a proven off-the-shelf embedded controller and custom electronics working in parallel with the standard OEM controller. The vehicle requires the addition of a secondary fuel system - primarily an additional set of fuel injectors which the New Eagle controller will drive. For the control system, the New Eagle design intercepts a number of I/Os in the base OEM control system to allow, for example, disabling of the OEM control of the injector signal and replacing this with the New Eagle system control of the secondary fuel injector. | |||

The | The introduction of an aftermarket component such as fueling into an OEM control loop will inevitably introduce gain and lag. The New Eagle system is designed to minimize the gain and lag introduced to the system by allowing on-cycle fueling adjustments and calibration of start of injection of the secondary fuel. The gain and lag that are introduced can cause instability in the OEM fueling control. The bi-fuel controller must allow the OEM control loop to drive to the correct engine output oxygen content. This means that a properly tuned system will have a different 'pedal to power' relationship on the secondary fuel when compared to the primary fuel. The system can be calibrated to operate on one fuel or the other at different engine conditions, allowing customization of the drive areas where most displacement is desired. Future system developments aim to utilize existing OEM fuel mapping to allow for bi-fuel operation without a change to the 'pedal to power' relationship. | ||

New Eagle is continuing to advance development of bi-fuel technology: looking at full OBDII compliance and what can be done with direct injection engines being the two highest priorities. | |||

== Dual-Fuel Diesel Engines == | |||

[[ | [[File:Df.JPG|frameless|400px |right]] | ||

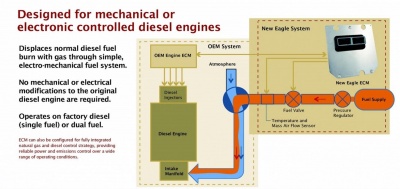

Dual-fuel engines are being introduced into the USA to blend low-cost natural gas into the inlet air stream of the engine. This is done to allow the burning of a less expensive fuel while retaining the advantages of a compression ignition engine. These engines have very few mechanical changes and a small amount of diesel is still required to provide the ignition energy for the combustion. The engine retains the efficiency of operation from the diesel cycle. In other parts of the world, similar combustion is being introduced with propane autogas as the secondary fuel. | |||

Natural gas is stored in either a compressed or liquid state. Both have their advantages and disadvantages. | |||

The New Eagle | |||

New Eagle | The advantages of natural gas as a transportation fuel are as follows: | ||

*The relative cost of natural gas compared to liquid fuels is advantageous | |||

*The carbon to hydrogen ratio is 4:1 meaning that there are fewer greenhouse gas emissions compared to liquid hydrocarbon fuels | |||

In the majority of systems, natural gas is introduced into the intake airflow post turbo and the quantity of diesel fuel injected is reduced by a dual-fuel control system. These control systems allow the engine to still operate on 100% diesel in the event the alternative fuel is not available. New Eagle is one of the primary suppliers of these control systems in the USA. | |||

In addition to providing the control system, New Eagle also supports the development of these products from initial design to emissions certification. | |||

Key aspects in the development: | |||

*Engines should not be "over-fueled," i.e., the energy added from natural gas cannot exceed the energy content of the diesel replaced otherwise high levels of methane emissions will result. | |||

*The engine's fueling must be properly calibrated to avoid engine-damaging pre-combustion "knock." | |||

*Engine emissions cannot be compromised. | |||

*Natural gas can change the exhaust temperature profile of the engine and must be accounted for to keep exhaust emissions devices properly operating. | |||

These issues require a complex control system, with aftermarket systems typically intercepting the throttle command signal from the driver and allowing the controller to control the reduction in diesel and map the natural gas replacement. New Eagle utilizes a torque-based control model to successfully achieve these requirements, with diesel flow rates during highway operation being comparable to normal idle operation. | |||

=Contact Us= | |||

Please '''[https://www.neweagle.net/contact/ contact us]''' for components inquiries or to work with our engineering team for supporting your projects. | |||

Latest revision as of 16:52, 28 February 2023

Introduction

New Eagle has experience in engine controls development for a range of alternative fuel applications. There is a push towards the use of alternative fuels in the transportation industry based on the reduced operating costs, decreased environmental impact and domestic availability. For consumption of alternative fuels to increase, infrastructure and vehicle solutions must be put in place. New Eagle is well placed to assist in supporting the need for vehicle solutions with low-volume product distribution and engineering support. New Eagle distributes high capability automotive controllers and engine control software, plus auxiliary displays, throttle bodies, injectors and other engine and vehicle components to companies producing alternative fuel solutions. In addition to hardware and software, New Eagle also provides engineering resources to support our customers in the development of the full range of alternative fuel systems and vehicles. This support can range from mechanical system integration through to complete engine control systems for all markets.

Alternative Fuel Components

New Eagle has an extensive supplier network to provide the best validated components at competitive prices. This offering includes a full set of components required for the design and assembly of alternative fuel vehicle systems. Please see our Engine Control page for more information on industrial parts and components, or use the "Products by Application" and "Products by Category" sections to search the wiki.

Alternative Fuel Systems

There is a range of applications which allows vehicles to operate on alternative fuels, and New Eagle has extensive experience on the most common examples of these: dedicated, bi-fuel and dual-fuel.

- Dedicated systems will operate on only one fuel - for example conventional diesel and gasoline engines are typically dedicated fuel engines. These engines can then be converted to operate "dedicated" on DME (from diesel) and CHG or propane autogas (from gasoline).

- Bi-fuel systems are designed to allow an engine to switch between a primary and a secondary alternative fuel during operation. Generally speaking, the engine can operate on either fuel at any time. Examples of this are bi-fuel gasoline/CNG and bi-fuel gasoline/propane autogas.

- Dual-fuel systems allow an engine to operate on a blend of the primary and alternative fuel sources, but the primary fuel must always be present. Examples of this are dual-fuel diesel/CNG compression ignition engines being introduced in many larger engines.

Notes:

- The definitions for bi-fuel and dual-fuel are swapped across the industry.

- For completeness, flex-fuel systems allow not just a switch between a primary and alternative fuel but also a blending of the two.

New Eagle has experience with the development of most of these types of systems for alternative fuel vehicles. The New Eagle engineering team has experience with safety-critical system development, vehicle integration, communication protocol standards and diagnostics, and this expertise is integrated into our solutions.

Certified Dedicated Alternative Fuel Heavy-Duty Spark-Ignited Engine

Powertrain Integration has developed an 8.0L, V8, naturally aspirated engine to operate on dedicated propane autogas fuel for various Freightliner truck and bus platforms. For this new engine configuration, New Eagle was chosen as the engine control system provider - supplying both the engine controller hardware and the full engine control model and strategy. The control system developed by New Eagle includes model-based torque estimation, torque limiters and arbitration as well as various OBD-specific physically based models. The controls system is designed to be safety critical and provides redundant monitoring of critical paths. This control system has been fully certified by CARB and U.S. EPA to meet 2013 on-highway standards.

The developed Engine Control Software has the following features:

- Pedal interpretation as torque requester

- Cruise control

- PTO control

- Torque limiting functions

- Torque arbitration (between pedal, cruise, PTO)

- Open-loop fuel control

- Close-loop fuel control

- Airflow characterizations and dynamics

- Idle control

- Deceleration fuel cutoff and safety fuel cutoff

- Ignition angle and energy characterization

- Engine torque characterization

- Forward path: friction and pumping losses, indicated engine torque to air charge characterization, modifiers for ignition retarding, temperature and pressure modifiers, equivalence ratio modifier, ignition angle offset request based on fast path torque, torque reserve request

- Reverse path: frictional and pumping losses, air charge to torque characterization, modifiers for ignition retarding, equivalence ratio modifier, temperature and pressure modifiers, fuel cutoff

- Slow path: throttle-based slow path torque delivers nominal torque plus torque reserve request

- Fast path: spark-based fast path torque delivers transient torque requests from torque reserve

- Modeled air charge

- Engine state determination

- Steady state determination

- Modeled temperatures

- Lambda

- Accessory control

- Throttle position control

- HEGO heater control

- Injector characterization

- Ignition angle and energy characterization

- Sensor rationalities for redundancy

- Secondary microprocessor rationalities

- OBDII Diagnostics

- OBDII Major monitors

- Fuel system monitor

- Catalyst monitor

- Catalyst temperature model

- Engine coolant temperature monitor

Bi-Fuel Gasoline CNG or Propane Autogas Engines

New Eagle has verified a bi-fuel system design which utilizes a proven off-the-shelf embedded controller and custom electronics working in parallel with the standard OEM controller. The vehicle requires the addition of a secondary fuel system - primarily an additional set of fuel injectors which the New Eagle controller will drive. For the control system, the New Eagle design intercepts a number of I/Os in the base OEM control system to allow, for example, disabling of the OEM control of the injector signal and replacing this with the New Eagle system control of the secondary fuel injector.

The introduction of an aftermarket component such as fueling into an OEM control loop will inevitably introduce gain and lag. The New Eagle system is designed to minimize the gain and lag introduced to the system by allowing on-cycle fueling adjustments and calibration of start of injection of the secondary fuel. The gain and lag that are introduced can cause instability in the OEM fueling control. The bi-fuel controller must allow the OEM control loop to drive to the correct engine output oxygen content. This means that a properly tuned system will have a different 'pedal to power' relationship on the secondary fuel when compared to the primary fuel. The system can be calibrated to operate on one fuel or the other at different engine conditions, allowing customization of the drive areas where most displacement is desired. Future system developments aim to utilize existing OEM fuel mapping to allow for bi-fuel operation without a change to the 'pedal to power' relationship.

New Eagle is continuing to advance development of bi-fuel technology: looking at full OBDII compliance and what can be done with direct injection engines being the two highest priorities.

Dual-Fuel Diesel Engines

Dual-fuel engines are being introduced into the USA to blend low-cost natural gas into the inlet air stream of the engine. This is done to allow the burning of a less expensive fuel while retaining the advantages of a compression ignition engine. These engines have very few mechanical changes and a small amount of diesel is still required to provide the ignition energy for the combustion. The engine retains the efficiency of operation from the diesel cycle. In other parts of the world, similar combustion is being introduced with propane autogas as the secondary fuel.

Natural gas is stored in either a compressed or liquid state. Both have their advantages and disadvantages.

The advantages of natural gas as a transportation fuel are as follows:

- The relative cost of natural gas compared to liquid fuels is advantageous

- The carbon to hydrogen ratio is 4:1 meaning that there are fewer greenhouse gas emissions compared to liquid hydrocarbon fuels

In the majority of systems, natural gas is introduced into the intake airflow post turbo and the quantity of diesel fuel injected is reduced by a dual-fuel control system. These control systems allow the engine to still operate on 100% diesel in the event the alternative fuel is not available. New Eagle is one of the primary suppliers of these control systems in the USA.

In addition to providing the control system, New Eagle also supports the development of these products from initial design to emissions certification.

Key aspects in the development:

- Engines should not be "over-fueled," i.e., the energy added from natural gas cannot exceed the energy content of the diesel replaced otherwise high levels of methane emissions will result.

- The engine's fueling must be properly calibrated to avoid engine-damaging pre-combustion "knock."

- Engine emissions cannot be compromised.

- Natural gas can change the exhaust temperature profile of the engine and must be accounted for to keep exhaust emissions devices properly operating.

These issues require a complex control system, with aftermarket systems typically intercepting the throttle command signal from the driver and allowing the controller to control the reduction in diesel and map the natural gas replacement. New Eagle utilizes a torque-based control model to successfully achieve these requirements, with diesel flow rates during highway operation being comparable to normal idle operation.

Contact Us

Please contact us for components inquiries or to work with our engineering team for supporting your projects.