|

|

| (30 intermediate revisions by 6 users not shown) |

| Line 1: |

Line 1: |

| __FORCETOC__ | | __FORCETOC__ |

|

| |

| =Controllers =

| |

| ==HCM-5604-36-1301 (CM0711)==

| |

| [[File:HCM-5604-036-1301.jpg|300px]]

| |

|

| |

| The HCM-5604-36-1303 (CM711) is a rugged CAN Controller designed for Mobile Hydraulics. Alternatively, this controller can also act as an additional controller in systems where the existing main controller does not provide enough I/O for the system. The CM0711 has closed loop current control,datalogging, and it is able to measure analog and digital input signals. Multiple modules on the system can be identified using addressing ID tag inputs built into the wire harness.

| |

|

| |

| ===FAQ ===

| |

| This device has 8 MB Flash for data logging.

| |

|

| |

| The compiler for the 0711 is CodeWarrior 2.10 for MPC55xx

| |

|

| |

| '''Datasheet'''

| |

|

| |

| Please '''[http://www.neweagle.net/support/wiki/index.php?title=Controllers#HCM-5604-36-1303_.28CM0711.29 Click Here]''' for datasheet.

| |

|

| |

| '''Webstore'''

| |

|

| |

| '''[mailto:sales@neweagle.net Please Contact Sales]'''

| |

|

| |

| ==HCM-5534-90-1201/1302 (CM3626)==

| |

| [[File:CM3626.jpg|200px]]

| |

|

| |

| The HCM-5534-90-1201 (CM3626) is a controller for vehicle and other applications with a steady voltage of less than or equal to 32 Vdc. It has 36 inputs and 26 outputs as well as 2 CAN/J1939 communication ports. The CM 3626 is especially suited for applications with higher demands on functional safety, where there is a need to prove the safety integrity of each implemented safety function. All outputs have diagnostics for both internal and external faults and, when used in safe mode, have return switches that provide a redundant shut down path. Two versions of the CM3626 are available, the HCM-5534-90-1201 with 768 kB of flash and the HCM-5534-90-1302 with an additional 2 MB of flash.

| |

|

| |

| ===FAQ ===

| |

| *Two part numbers are available for the 3626. The 1302 has an additional 2 MB FLASH & 512 KB RAM memory available.

| |

|

| |

| *What is the frequency range for the frequency inputs?

| |

|

| |

| Both modules have a 10kHz max frequency. The CM3626 user guide also indicates that there is a minimum 1kHz frequency.

| |

|

| |

| *What is the 5V reference output voltage and current rating?

| |

|

| |

| Both have a selectable 5V or 8V reference output. The CM2115 is rated for 300mA and the CM3626 is rated for 1A

| |

|

| |

| * One CAN channel is listed as 205K and the other 250/500, does this mean that one channel only supports 250K?

| |

|

| |

| Correct, we have a change in the works for HCM-5534-90-1302 that would allow 500K on CAN1 as well.

| |

|

| |

| * The calibration interface isn’t specified, what do they support (CCP/XCP/other)?

| |

|

| |

| XCP – Compliant A2L file are generated for use with CANAPE, VISION, etc...

| |

|

| |

| *Many of the PWM outputs have either a 250Hz or 500Hz max frequency, is this correct?

| |

|

| |

| Many do but not all. Note, the CM2115 LSOs can PWM at 1500Hz.

| |

|

| |

|

| |

| '''Datasheet'''

| |

|

| |

| Please '''[http://www.neweagle.net/support/wiki/index.php?title=Controllers#HCM-5534-90-1201.2F1302_.28CM3626.29 Click Here]''' for datasheets.

| |

|

| |

| '''Webstore'''

| |

|

| |

| '''[mailto:sales@neweagle.net Please Contact Sales]'''

| |

|

| |

| ==HCM-5534-50-1203 (CM2115)==

| |

| [[File:HCM-PHC-CM2115.jpg|300px]]

| |

|

| |

| The HCM-5534-50-1203 (CM2115) offers a durable solution for your hydraulic control needs. With a die cast aluminium and molded plastic housing this module can withstand the harshest of environments. This module has 21 inputs, 15 outputs and 2 CAN communication channels, which allows the module to have great I/O flexibility. This module also has fault protection, assuring that functions can be carried out safely.

| |

|

| |

| ===FAQ===

| |

| * What CAN rates are supported with the Raptor CM2115? CAN1 only supports 250K, CAN2 supports 250K or 500K, Standard (11-bit) and Extended (29-Bit) messaging is supported.

| |

|

| |

| '''Datasheets'''

| |

|

| |

| Please '''[http://www.neweagle.net/support/wiki/index.php?title=Controllers#HCM-5534-50-1203_.28CM2115.29 Click Here]''' for datasheets.

| |

|

| |

| '''Webstore'''

| |

|

| |

| '''[http://store.neweagle.net/products-by-tools/raptor-target-hardware/controllers/5534-50-raptortm-hydraulic-control-module-cm2115.html Buy Now]'''

| |

|

| |

| ==HCM-ARM4-70-1401 (CM3620)==

| |

| [[File:CM3620.jpg|300px]]

| |

|

| |

| The Controller Module (CM) 3620 is an input/output controller that monitors digital, analog and frequency inputs, and controls solid-state switched outputs.

| |

|

| |

| ===FAQ ===

| |

| What CAN rates are supported with the Raptor CM3620? CAN1 & CAN2 only support 250K. CAN2 support for receiving extended 29bit IDs not available now.

| |

|

| |

| '''Datasheets'''

| |

|

| |

| Please '''[http://www.neweagle.net/support/wiki/index.php?title=Controllers#HCM-ARM4-70-1401_.28CM3620.29 Click Here]''' for datasheets.

| |

|

| |

| '''Webstore'''

| |

|

| |

| '''[mailto:sales@neweagle.net Please Contact Sales]'''

| |

|

| |

| ==GCM-1793-196-15031 (GCM196)==

| |

| [[File:ECM196.png|300px]]

| |

|

| |

| The GCM196 is a 196-pin General Control Module suitable for time-based controls applications with high I/O counts.

| |

|

| |

| ===FAQ ===

| |

|

| |

| '''Datasheets'''

| |

|

| |

| Please '''[http://www.neweagle.net/support/wiki/index.php?title=Raptor-Controllers#GCM196 Click Here]''' for datasheets.

| |

|

| |

| '''Webstore'''

| |

|

| |

| '''[mailto:sales@neweagle.net Please Contact Sales]'''

| |

|

| |

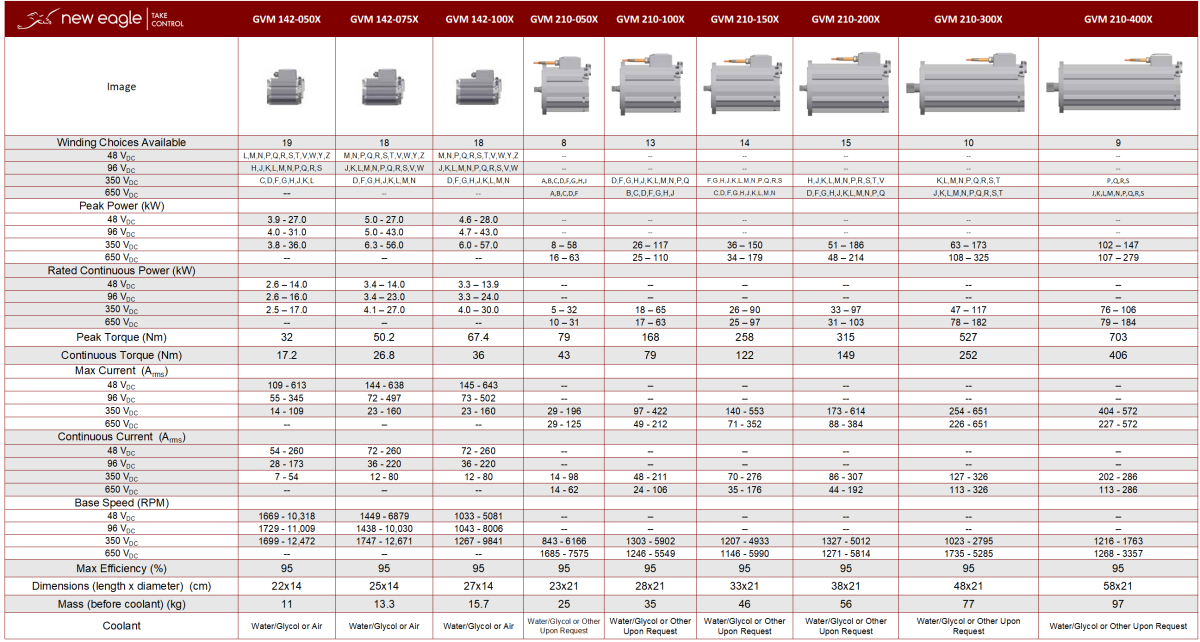

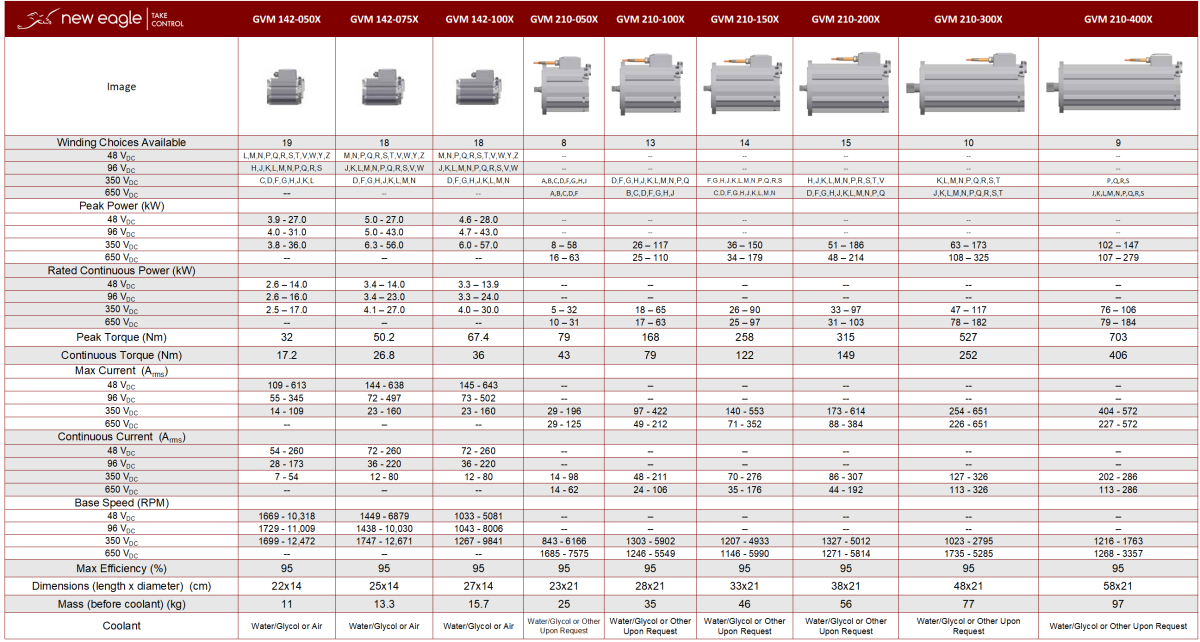

| =EV Motors= | | =EV Motors= |

| [[File:Parker.png|1200px]]<br> | | [[File:Parker.png|1200px]]<br> |

| Line 109: |

Line 5: |

| [[image:GVM142.png|300px]] | | [[image:GVM142.png|300px]] |

|

| |

|

| The GVM 142 Motors are a versatile line of motors that can operate at up to 95% efficiency. General applications include Motor Generator Units, or e-accessories such as electric power steering. The GVM 142 line of motors can be optimized for specific speed and torque points for a user system. Lastly, Parker offers their unique cooling configuration features that can increase power density significantly. | | The GVM 142 Motors are a versatile line of motors that can operate at up to 95% efficiency. General applications include motor generator units or e-accessories, such as electric power steering. The GVM 142 line of motors can be optimized for specific speed and torque points for a user's system. Lastly, Parker offers their unique cooling configuration that can increase power density significantly. |

| | |

| ===FAQ ===

| |

| Can be used for a Permanent Magnet Alternator or Generator solution for Hybrid Vehicle Applications

| |

| | |

| '''Datasheets'''

| |

|

| |

|

| Please '''[http://www.neweagle.net/support/wiki/index.php?title=EV-Components#Parker_Motors Click Here]''' for datasheets.

| | === Frequently Asked Questions (FAQ) === |

| | The GVM 142 can be used as a permanent magnet alternator or as a generator solution for hybrid vehicle applications. |

|

| |

|

| '''Webstore''' | | ===Downloads=== |

| | :'''[https://wiki.neweagle.net/ProductDocumentation/EVsoftwareAndHardware/ElectricMotors/Parker/GVM_Motor_Datasheet.pdf Datasheet]''' |

|

| |

|

| '''[mailto:sales@neweagle.net Please Contact Sales]''' | | ===Webstore=== |

| | See our '''[https://store.neweagle.net/product-category/our-markets/electric-hybrid/electric-motors/ webstore]''' for more electric motors. |

|

| |

|

| ==GVM 210== | | ==GVM 210== |

| [[File:GVM_210.png|300px]] | | [[File:GVM_210.png|300px]] |

|

| |

|

| The GVM 210 series of Traction motors by Parker are a flexible and durable line of Electric motors. Their Main advantages in the many configurations that they are available in. Configuration options include voltage, rotor length, and winding variation. The GVM 210 series is also offered with Parker's unique cooling configuration that has minimal impact on size and weight. | | The GVM 210 series of traction motors by Parker are a flexible and durable line of electric motors. Their main advantage is in the many configurations that they are available in. Configuration options include voltage, rotor length and winding variation. The GVM 210 series is also offered with Parker's unique cooling configuration that has minimal impact on size and weight. |

| | |

| '''Datasheets'''

| |

|

| |

|

| | ===Downloads=== |

| | :'''[https://wiki.neweagle.net/ProductDocumentation/EVsoftwareAndHardware/ElectricMotors/Parker/GVM_Motor_Datasheet.pdf Datasheet]''' |

|

| |

|

| Please '''[http://www.neweagle.net/support/wiki/index.php?title=EV-Components#Parker_Motors Click Here]''' for datasheets.

| | ===Webstore=== |

|

| |

|

| '''Webstore'''

| | See our '''[https://store.neweagle.net/product-category/our-markets/electric-hybrid/electric-motors/ webstore]''' for more electric motors. |

| | |

| '''[mailto:sales@neweagle.net Please Contact Sales]''' | |

|

| |

|

| =AC Motor Controllers - Inverters= | | =AC Motor Controllers - Inverters= |

| Line 141: |

Line 33: |

| [[File:Parker_inverter.png]] | | [[File:Parker_inverter.png]] |

|

| |

|

| Parker’s MA3 Series inverter combines high performance motor control with intelligent control functionality. Suitable for | | Parker’s MA3 Series inverter combines high performance motor control with intelligent control functionality. Suitable for either PMAC or AC induction motors, it also offers the flexibility of several feedback options. Speed and torque points can be adjusted instantaneously, and the performance algorithms are optimized to the vehicle’s needs. On-board digital communications with multiple protocols come standard, along with a USB programming port. The rugged cast aluminum housing integrates a proprietary cooling configuration and necessary environmental protection for the toughest mobile applications. |

| either PMAC or AC induction motors, it also offers the flexibility of several feedback options. Speed and torque points can | |

| be adjusted instantaneously and performance algorithms optimized to the vehicle’s needs. On-board digital communications | |

| with multiple protocols come standard, along with a USB programming port. The rugged cast aluminum housing integrates | |

| a proprietary cooling configuration and necessary environmental protection for the toughest mobile applications. | |

|

| |

|

| | ===Downloads=== |

| '''[http://neweagle.net/support/wiki/docs/parker/MA3ProductFlyerRev5.pdf MA3 Product Flyer]''' | | '''[http://neweagle.net/support/wiki/docs/parker/MA3ProductFlyerRev5.pdf MA3 Product Flyer]''' |

|

| |

|

| Line 152: |

Line 41: |

|

| |

|

| =Contact Sales= | | =Contact Sales= |

| For more information on Parker products, '''[http://www.neweagle.net/contact.html Contact Sales]''' | | For more information on Parker products, please contact '''[https://www.neweagle.net/contact/ sales]'''. |

| | |

| | =Other Modules= |

| | '''[[Controllers | Controllers]]''' |

EV Motors

GVM 142

The GVM 142 Motors are a versatile line of motors that can operate at up to 95% efficiency. General applications include motor generator units or e-accessories, such as electric power steering. The GVM 142 line of motors can be optimized for specific speed and torque points for a user's system. Lastly, Parker offers their unique cooling configuration that can increase power density significantly.

Frequently Asked Questions (FAQ)

The GVM 142 can be used as a permanent magnet alternator or as a generator solution for hybrid vehicle applications.

Downloads

- Datasheet

Webstore

See our webstore for more electric motors.

GVM 210

The GVM 210 series of traction motors by Parker are a flexible and durable line of electric motors. Their main advantage is in the many configurations that they are available in. Configuration options include voltage, rotor length and winding variation. The GVM 210 series is also offered with Parker's unique cooling configuration that has minimal impact on size and weight.

Downloads

- Datasheet

Webstore

See our webstore for more electric motors.

AC Motor Controllers - Inverters

Parker MA3 Series Inverters

Parker’s MA3 Series inverter combines high performance motor control with intelligent control functionality. Suitable for either PMAC or AC induction motors, it also offers the flexibility of several feedback options. Speed and torque points can be adjusted instantaneously, and the performance algorithms are optimized to the vehicle’s needs. On-board digital communications with multiple protocols come standard, along with a USB programming port. The rugged cast aluminum housing integrates a proprietary cooling configuration and necessary environmental protection for the toughest mobile applications.

Downloads

MA3 Product Flyer

Parker Mobile Inverters, Motors, and ePumps Brochure

Contact Sales

For more information on Parker products, please contact sales.

Other Modules

Controllers