Gaseous Fuel Controls: Difference between revisions

| (One intermediate revision by the same user not shown) | |||

| Line 1: | Line 1: | ||

== Gaseous Fuel Control Archive == | |||

The Gaseous Fuel Control section of our wiki is an archive of former projects only and not specifically a current offering of the New Eagle engineering team. Please contact '''[mailto:sales@neweagle.net sales]''' if you have a need or question on any of the content herein. | |||

==Overview== | |||

New Eagle engineers offer system engineering and custom embedded control systems solutions including system designs, development, and integration tools and processes. Services that are provided by New Eagle include controls, production software testing, component and hardware selection and development, user interface devices, and long-term customer support. | New Eagle engineers offer system engineering and custom embedded control systems solutions including system designs, development, and integration tools and processes. Services that are provided by New Eagle include controls, production software testing, component and hardware selection and development, user interface devices, and long-term customer support. | ||

Latest revision as of 15:01, 23 February 2023

Gaseous Fuel Control Archive

The Gaseous Fuel Control section of our wiki is an archive of former projects only and not specifically a current offering of the New Eagle engineering team. Please contact sales if you have a need or question on any of the content herein.

Overview

New Eagle engineers offer system engineering and custom embedded control systems solutions including system designs, development, and integration tools and processes. Services that are provided by New Eagle include controls, production software testing, component and hardware selection and development, user interface devices, and long-term customer support.

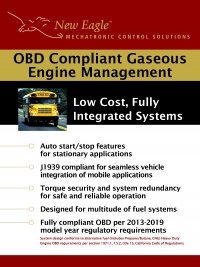

LPG Engine Control

New Eagle has experience developing gaseous engine systems for both stationary and over-the-road applications. New Eagle uses its library of engine controls, its production-qualified engine control hardware and the MotoHawk code generation platform to develop gaseous engine control solutions for our customers.

Features of these systems include:

- Automotive quality and prices for components including sensors, throttles and engine controllers

- Enhanced user interface for engine control and system installation and setup

- Auto Start/Stop features for scheduled duty cycle or remote engine and load control

- Fuel efficiency advantages by utilizing automotive-style torque control algorithms

- OBD diagnostics to protect engine and other system components

- Adaptive to multiple fuel usage

- Adaptable controls for mobile and stationary applications

- Experience with vapor-lock handling and purge routines

For detailed information on our gaseous engine projects, please refer to our gaseous engine case studies at OBD Compliant LPG Engine Conversion or Natural Gas Engine with Variable Energy Adjustment.

Contact Sales

Please contact us to discuss your engine management needs.

Mixed-Fuel (Dual-Fuel) Diesel Engine Controls

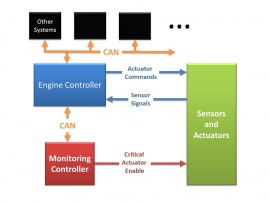

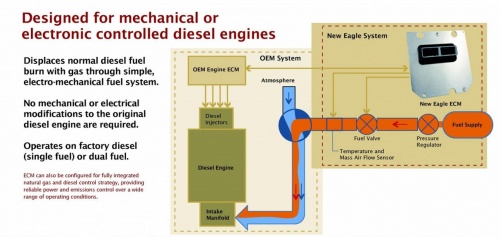

New Eagle engineers have worked to help customers build dual-fuel (diesel/CNG) control systems to reduce the fuel cost of stationary and mobile applications, both certified and uncertified. The MotoHawk toolchain is an ideal product for such an application.

- Allow existing diesel engines to safely substitute natural gas ranging from 65% to 80%

- Mileage dramatically increases due to burn rate and efficiency of diesel combustion

- Market payback: occurs within months, depending upon price of fuel

- Seamless integration with existing vehicle systems via CAN:

- Transmission

- Chassis

- Body

- Instrument clusters

Contact Sales

Please contact us and we can introduce you to a supplier with a system for you.

Bi-Fuel CNG

Would you like to drive the hybrid vehicle of tomorrow? The hybrid is a CNG option to your gasoline vehicle. New Eagle is developing a bi-fuel CNG fuel system for both PFI and DI injection gasoline engines.

Our Port-Fuel Injection kit is available for configuration to both GM and Ford pick-up and other light-duty vehicles. The Direct Injection is still in development and is expected in 2014.

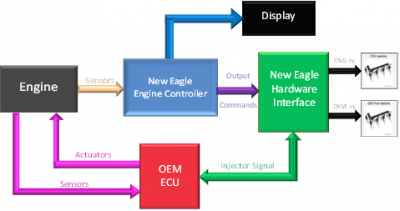

System Operation

New Eagle’s controls engineers are modifying the original fuel system into a retrofit bi-fuel CNG sequential fuel system. The new system intercepts the OEM ECU injector signals with a translator box that acts as a switch to cycle in and out of CNG while keeping the OEM ECU's diagnostics in control.

The New Eagle system can be biased to use more CNG or gasoline depending upon the customer's driving conditions and requirements. The most important feature is that our system can run on either gasoline only or a mix of CNG and gasoline. No more do you have to worry about running out of fuel and trying to find a CNG station.

Contact Sales

Please contact us to inquire about our status and an opportunity to drive one of our vehicles.