Alternative Fuel Vehicles: Difference between revisions

No edit summary |

No edit summary |

||

| Line 28: | Line 28: | ||

. | . | ||

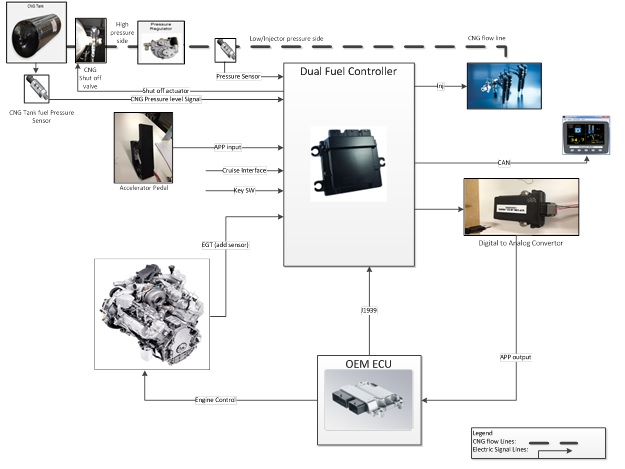

[[image:DFCS Overview.jpg|frameless| | [[image:DFCS Overview.jpg|frameless|800px |left]] | ||

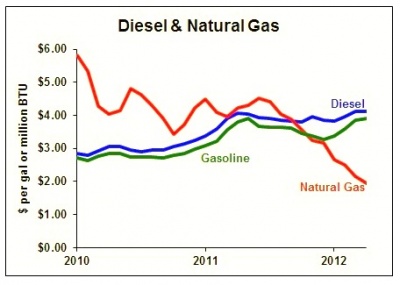

[[image:DFCS CompareFuel.jpg |frameless|400px | | [[image:DFCS CompareFuel.jpg |frameless|400px |center]] | ||

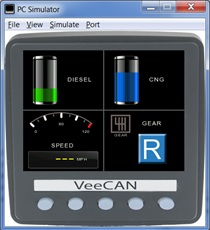

[[image:DFCS Display.jpg|frameless|400px | | [[image:DFCS Display.jpg|frameless|400px |center]] | ||

Revision as of 16:01, 2 December 2013

Introduction

- CARB Certified heavy duty spark ignited engines

- Dual-Fuel - Alt Fuel + Diesel Engines

- Bi-Fuel - alt fuel + gasoline Engines

Capability Overview

New Eagle has experience in engine controls development for a range of alternative fuels applications. New Eagle has developed dedicated engine control software for a heavy duty propane application that is certified by CARB. New Eagle has supported concept validation efforts for hybrid fuel systems such as mixed fuel (dual fuel) diesel and bi-fuel gasoline applications. The New Eagle engineering team has experience with safety-critical system development, vehicle integration, communication protocol standards, and diagnostics.

Example Applications

Certified Heavy Duty Spark Ignited Engine

. .

Bi-Fuel Gasoline Engines

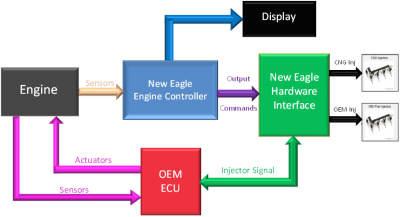

New Eagle has verified a Bi-Fuel system design which utilizes a proven off-the-shelf embedded controller and custom electronics for use in the aftermarket. The system design involves rerouting the OEM injector signals through the New Eagle system so that they can be disabled in order to allow operation on the secondary fuel. A secondary fuel system is installed with an additional set of fuel injectors which the New Eagle controller will drive.

The introduction of an aftermarket component into an OEM control loop such as fueling will inevitably introduce gain and lag. The New Eagle system is designed to minimize the gain and lag introduced to the system by allowing on-cycle fueling adjustments and calibration of start of injection of the secondary fuel. The gain and lag that are introduced can cause instability in the OEM fueling control. The Bi-Fuel controller must allow the OEM control loop to drive to the correct engine output oxygen content. This means that a properly tuned system will have a different 'pedal to power' relationship on the secondary fuel when compared to the primary fuel. The The system can be calibrated to operate on one fuel or the other at different engine conditions, to allow for customization of the drive areas where most displacement is desired. Future system developments aim to utilize existing OEM fuel mapping to allow for bi-fuel operation without a change to the 'pedal to power' relationship.

New Eagle is continuing to advance development of Bi-Fuel technology. We are currently investigating OBD-II compliance, port injection and direction injection variants, and multiple vehicle platforms.

Dual Fuel Diesel Engines

. .