Controllers: Difference between revisions

(→ECM) |

No edit summary |

||

| Line 153: | Line 153: | ||

:Module families: | :Module families: | ||

::*VCM-5567-46 | ::*VCM-5567-46 | ||

=General Hardware= | |||

==Voltage Specifications for Modules== | |||

While all the modules are designed to withstand momentary short-to-battery on the input sensor pins (except those that inherently cannot be protected), the hardware validation test is typically 1 minute short-to-battery. | |||

In the case of analog and digital inputs (nominal 5-volt), the circuit may not be able to dissipate heat when connected to a higher voltage on a longer timeframe. For instance, the pull-up or pull-down resistor may not be sized to dissipate heat from that higher voltage (resistor wattage rating). | |||

+++++ | |||

For the circuits marked "16V okay" in the table below, the resistor wattage rating is such that continuous operation at 16V should be okay. | |||

"Double Battery" situation: If there is a particular circuit, let me know and we can check. At nominal 24V (as high as 32V jumpstart), the trace widths as well as the PU/PD resistor may be vulnerable. Some of the pull-downs would likely be okay, but this should be verified. For example, AN4: 220k-ohm pull-down ---> P = V2 / R = 32*32 / 220e3 = 0.005 W = 5 mW. The resistor for AN4 is rated 63 mW. Depending on ambient temperature for module (heat transfer from resistor, to module body, to ambient), this circuit may be okay for short "double battery" exposure. | |||

[[Image:Chart_2.JPG|center]] | |||

==H-bridge Wiring== | |||

The H-bridge is normally wired as: | |||

(H+)----(load)----(H–) | |||

and the H-bridge circuit is powered from DRVP internally. | |||

(BATT)----(MPR Common, MPR Normally Open)----(DRVP)----(to H-bridge and other internal devices, and flyback diodes). | |||

The low side of the H-bridge circuitry connects to DRVGx and then back to battery ground. | |||

==ECM Differences== | |||

{| {{table}} | |||

| align="center" style="background:#c0c0c0;"|'''MotoHawk Target''' | |||

| align="center" style="background:#c0c0c0;"|'''Current MotoTron part numbers (What to ask for When Ordering)''' | |||

| align="center" style="background:#c0c0c0;"| | |||

|- | |||

| ECM-0555-048-0706||EC-0555-048-0701 (-0706 not produced, replaces -none-)||<--VR crank | |||

|- | |||

| ECM-0555-048-0707||ECM-0555-048-0707 (-0702 no produced, Replaces -0402)||<--VR crank | |||

|- | |||

| ECM-0555-048-0708||ECM-0555-048-0708 (-0703 not produced, replaces 0401)||<--Diital/Hall crank | |||

|- | |||

| ECM-0555-048-0709||ECM-0555-048-0704 (0809 not produced, replaces -0401)||<--VR crank | |||

|- | |||

| ECM-0555-048-0710,||ECM-0555-048-0710 (-0705 not produced, replaces -0403)||<--VR crank (either | |||

|- | |||

| ECM-0555-048-0403||||MH target should work) | |||

|- | |||

| | |||

|} | |||

==Implementing J1587 Protocol on a J1708 hardware layer (using a MotoTron RS485 Driver)== | |||

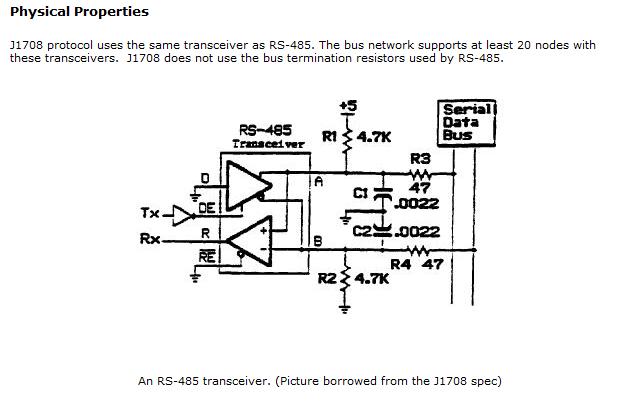

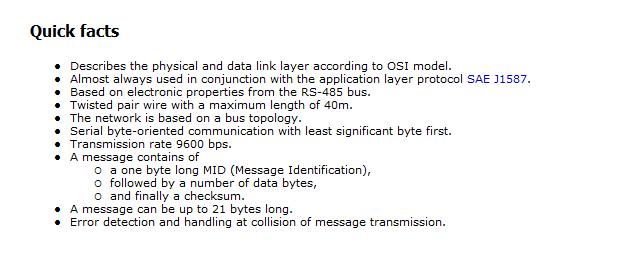

A RS485 software driver in MotoHawk can be written for J1587. The hardware signal conditioning and some general J1587 notes follow: | |||

[[Image:PhysProp.JPG]] | |||

[[Image:QFacts.JPG]] | |||

Revision as of 13:37, 7 July 2010

Introduction to New Eagle Controllers

New Eagle Control Module Naming Scheme

The New Eagle naming scheme is broken into four main parts: type of control module, type of microprocessor, number of pins, and model year & variant. An extra sequence of numbers/letters may be seen at the end which determine certain model features such as flash, calibratible, or mounting feet.

What does this mean?

ECM-565-128-0701-C

- Start by looking at the first section which determines the type of control model. The model in the above example is an ECM (Engine Control Module) as opposed to a GCM (General Control Module), HCM (Hydraulic Control Module), EVM (Electric Vehicle Module), or VCM (Vehicle Control Module)

- The second part describes the type of microprocessor the module has. The above module has a MPC565 Microprocessor.

- The third part shows the number of pins that the module has. The example module has 128 pins.

- The fourth section consists of the model year and the model variant. In the above example, the control model has a model year of 2007 and is the first variant.

- The last section that may appear when naming modules determines certain features that the model may have. 'C' stands for Calibratible - thus the above module is calibratible. Other Endings may include 'F' (Flash), 'M' (Mounting Feet), 'CPO' (Calibratible "DEV" Development Module), and 'F00' (Flash "PROD" Production Module).

Module Naming Quick Cheat Sheet:

Module: ECM-555-80-xxyy-CP0/F00

ECM = engine control module

555 = MPC 555 microprocessor

80= 80 pins

xx = model year (e.g. 07 = 2007 model year)

yy = variant of 80-pin model for xx model year (e.g. 03 = third variant).

-CP0 = calibratable "DEV" development module

-F00 = flash "PROD" production module

The last two letters are important for modules in development, not to be confused with a development module. The letters change as they develop or move from concept to release. The final letters are F00 meaning production.

New Eagle Module Part Overview

File:Module Family Overview.JPG

MotoHawk Control Solutions

[ MotoHawk Control Solutions]

Controllers

ECM

Engine control modules (ECM) differ from the general and hydraulic in that some inputs and outputs are customized for engine performance.

ECMs custom outputs for:

- Fuel Injection

- Spark Timing

ECM custom inputs for:

- Oxygen Sensors

- Knock Sensors

Signal Conditioning Includes:

- Inputs:

- Numerous Analog Inputs

- VR/Hall Frequency Inputs

- Outputs:

- Low Side Injector Drivers

- TTL Level Ignition System Outputs

- High Current Low Side PWM

- 5A H-Bridge PWM with Current Feedback

- Independent Transducer Power Supply

- Low Side Relay Driver (Main Power)

- Datalinks:

- CAN 2.0B Channel

Module families:

- ECM-555-48

- ECM-555-80

- ECM-563-48

- ECM-565-128

- ECM-S12-24

- ECM-5553-112

- ECM-5554-112

- ECM-XC2-24

Learn More About MotoHawk Engine Control Modules

GCM

Inputs and outputs for the General Purpose line of controllers include:

- Inputs:

- 11 to 18 Analog

- 2 to 8 Discrete/Frequency

- 0 to 2 Hall Effect Frequency (cam)

- 0 or 2 Variable Reluctance Frequency (crank)

- 1 Stop

- Outputs:

- 6 Low Side Driver

- 2 High Side Driver

- 1 H-Bridge Driver (10A)

- 1 Digital

- 1 Main Power Relay Driver

- Datalinks:

- Up to 3 CAN 2.0B Channels

Model families:

- GCM-563-48

- GCM-565-24

- GCM-S12-24

- GCM-S12-XX

- GCM-S12-36

HCM

Inputs and outputs for the Hydraulic line of controllers include:

- Inputs:

- Up to 16 Analog

- Up to 6 Discrete/Frequency

- Up to 2 VR/Hall Frequency

- 1 Knock/Drive Noise Detector

- 1 Stop

- Outputs:

- 6 2.5A Low Side Drivers w/Current Feedback

- 4 3A Low Side Drivers

- 1 1A EasyLink/Low Side Driver

- 1 Relay Driver (Main Power)

- Datalinks:

- 2 CAN 2.0B Channels

- Module families:

- HCM-563-48

EVM

Electric Vehicle Modules:

- Module families:

- EVM-55XX-24

VCM

Vehicle Control Modules:

- Module families:

- VCM-5567-46

General Hardware

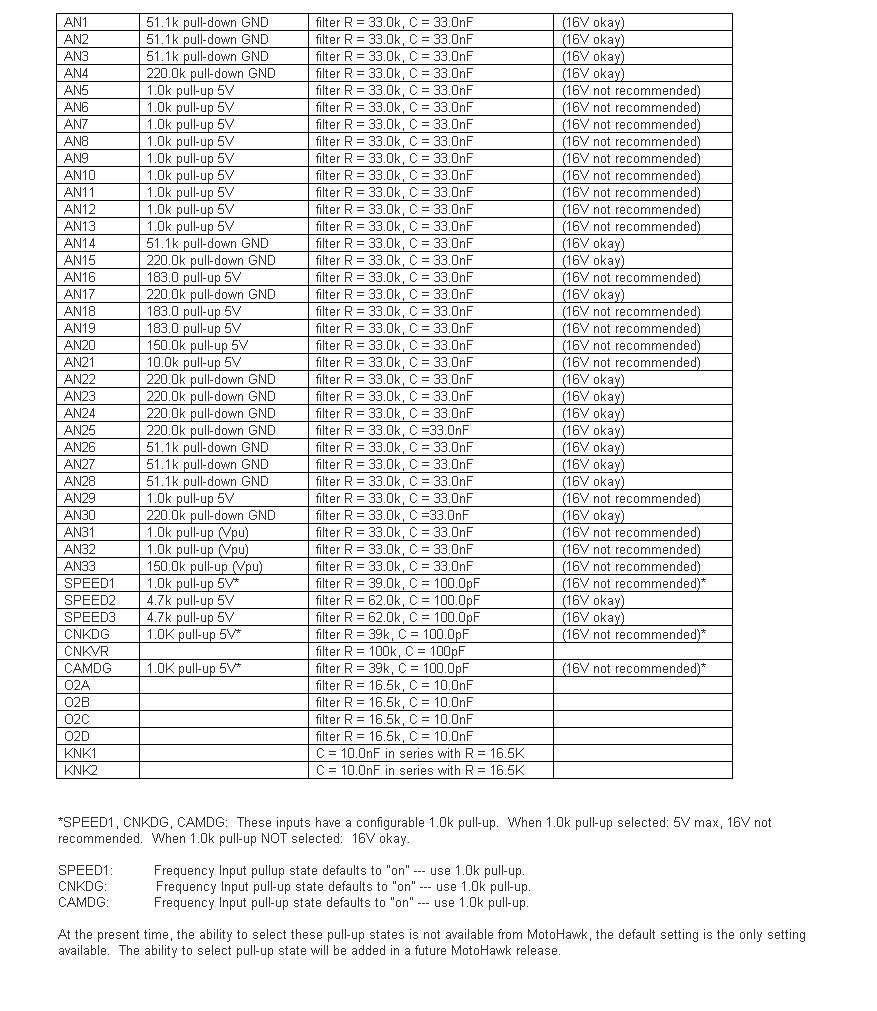

Voltage Specifications for Modules

While all the modules are designed to withstand momentary short-to-battery on the input sensor pins (except those that inherently cannot be protected), the hardware validation test is typically 1 minute short-to-battery.

In the case of analog and digital inputs (nominal 5-volt), the circuit may not be able to dissipate heat when connected to a higher voltage on a longer timeframe. For instance, the pull-up or pull-down resistor may not be sized to dissipate heat from that higher voltage (resistor wattage rating).

+++++

For the circuits marked "16V okay" in the table below, the resistor wattage rating is such that continuous operation at 16V should be okay.

"Double Battery" situation: If there is a particular circuit, let me know and we can check. At nominal 24V (as high as 32V jumpstart), the trace widths as well as the PU/PD resistor may be vulnerable. Some of the pull-downs would likely be okay, but this should be verified. For example, AN4: 220k-ohm pull-down ---> P = V2 / R = 32*32 / 220e3 = 0.005 W = 5 mW. The resistor for AN4 is rated 63 mW. Depending on ambient temperature for module (heat transfer from resistor, to module body, to ambient), this circuit may be okay for short "double battery" exposure.

H-bridge Wiring

The H-bridge is normally wired as: (H+)----(load)----(H–) and the H-bridge circuit is powered from DRVP internally. (BATT)----(MPR Common, MPR Normally Open)----(DRVP)----(to H-bridge and other internal devices, and flyback diodes). The low side of the H-bridge circuitry connects to DRVGx and then back to battery ground.

ECM Differences

| MotoHawk Target | Current MotoTron part numbers (What to ask for When Ordering) | |

| ECM-0555-048-0706 | EC-0555-048-0701 (-0706 not produced, replaces -none-) | <--VR crank |

| ECM-0555-048-0707 | ECM-0555-048-0707 (-0702 no produced, Replaces -0402) | <--VR crank |

| ECM-0555-048-0708 | ECM-0555-048-0708 (-0703 not produced, replaces 0401) | <--Diital/Hall crank |

| ECM-0555-048-0709 | ECM-0555-048-0704 (0809 not produced, replaces -0401) | <--VR crank |

| ECM-0555-048-0710, | ECM-0555-048-0710 (-0705 not produced, replaces -0403) | <--VR crank (either |

| ECM-0555-048-0403 | MH target should work) | |

Implementing J1587 Protocol on a J1708 hardware layer (using a MotoTron RS485 Driver)

A RS485 software driver in MotoHawk can be written for J1587. The hardware signal conditioning and some general J1587 notes follow: