Raptor-VeeCAN-320-Family: Difference between revisions

| Line 9: | Line 9: | ||

[[image:Veecanraptor-example.png|400px]] | [[image:Veecanraptor-example.png|400px]] | ||

A Raptor VeeCAN user can receive messages on the CAN bus and read a VeeCAN's analog inputs ( | A Raptor VeeCAN user can receive messages on the CAN bus and read a VeeCAN's analog inputs (three modes: 0-2.5V, 0-10V, 0-500Ω). The VeeCAN supports logging to an attached USB memory stick. | ||

[[image:Raptorveecan_logging.JPG|400px]] | [[image:Raptorveecan_logging.JPG|400px]] | ||

Revision as of 14:22, 20 February 2023

Raptor VeeCAN 320

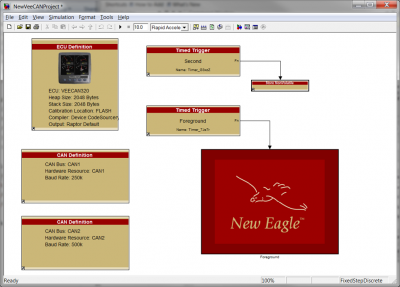

The Raptor VeeCAN 320 display uses the Raptor Development software tool to create a display interface for your application. New Eagle adapted the VeeCAN SDK to the Raptor platform. The Raptor VeeCAN platform allows model-based designers to engineer both the display logic and control logic for an HMI (Human Machine Interface).

The Raptor VeeCAN has a template starter project. It provides a base project with CAN logging, control logic and custom screens.

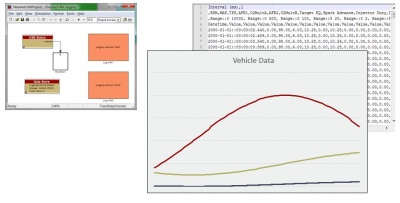

A Raptor VeeCAN user can receive messages on the CAN bus and read a VeeCAN's analog inputs (three modes: 0-2.5V, 0-10V, 0-500Ω). The VeeCAN supports logging to an attached USB memory stick.

Note: The file <usbstick_logoffload.autorun> must be on the USB memory stick to aid the VeeCAN in logging data. Download the file here: usbstick_logoffload.autorun.

Platform Benefits

- Model-based programming facilitates ease of use and rapid development of displays

- Read and log CAN messages

- Same great benefits of the VeeCAN 320

Downloads

Raptor VeeCAN 320 Lite

The Raptor VeeCAN 320 Lite display uses the Raptor Development software tool to create a display interface for your application. New Eagle adapted the VeeCAN SDK to the Raptor platform. The Raptor VeeCAN platform allows model-based designers to engineer both the display logic and control logic for an HMI (Human Machine Interface). The VeeCAN 320 Lite only has a single CAN channel (unlike the VeeCAN 320 which has two CAN channels and a 13 pins of I/O) and is best suited for applications with CAN sensors.

The Raptor VeeCAN has a template starter project. It provides a base project with CAN logging, control logic and custom screens.

Note: The file <usbstick_logoffload.autorun> must be on the USB memory stick to aid the VeeCAN in logging data. Download the file here: usbstick_logoffload.autorun.

Platform Benefits

- Model-based programming facilitates ease of use and rapid development of displays

- Read and log CAN messages

- Same great benefits of the VeeCAN 320 but with fewer I/O and CAN channels

- Best suited for applications with CAN-based sensors

Downloads

VeeCAN 320 Display Examples

- A selection of displays created on the Raptor VeeCAN 320

-

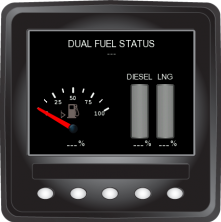

Example of a fuel gauge and fuel status screen

-

A collection of dials showing engine information

-

A custom Raptor screen showing the battery meter, vehicle speed and engine speed

-

A very simple Raptor system information screen and menu

-

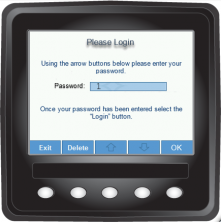

Anything is possible in Raptor, even a login screen such as this

-

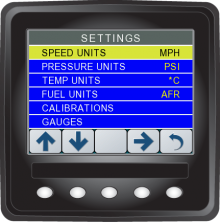

Raptor's customization is shown heavily in this custom menu screen

-

A custom system menu screen capable of controlling the whole display

-

Raptor's possibilities are endless with customs displays like this one