Telematics: Difference between revisions

| Line 150: | Line 150: | ||

====Configuration File Tool==== | ====Configuration File Tool==== | ||

'''[http://www.neweagle.net/support/wiki/docs/Datasheets/datalogger/NewEagle.DataLogger.ToolSuite.v1.0.0.2.zip New Eagle CANLogger Configuration File Program]''' | '''[http://www.neweagle.net/support/wiki/docs/Datasheets/datalogger/NewEagle.DataLogger.ToolSuite.v1.0.0.2.zip New Eagle CANLogger Configuration File Program]''' | ||

====Software Update ==== | |||

The file to update the Datalogger can be downloaded here, '''[http://www.neweagle.net/support/wiki/docs/Datasheets/datalogger/Firmware.bin Update File]'''. | |||

==== Datasheets ==== | ==== Datasheets ==== | ||

Revision as of 19:52, 8 October 2012

New Eagle Telematics Solutions

The Telematics board is our standalone unit that can perform a multitude of functions from CAN data-aggregation and analytic processing to real-time vehicle monitoring through available Cell/Wi-fi networks. It can communicate desired parameter information to the base station in the form of raw CAN data, web browser interfaces and text/email alerts. Compatibility with MotoHawk development environment provides us a means of its smooth integration with your CAN bus systems.

Telematics Board

The Telematics board preforms real-time Vehicle network monitoring, non-network data aggragation, and analytic processing with optional telematics functionality in a compact standalone unit. It can be easily integrated into new vehicles or as a retrofit onto legacy platforms. The functionality records critcal parameters such as asset health, GPS location, diagnostic trouble codes and system data in persistent storage until downloaded. This process ensures that all data is captured even when Wi-Fi and Cell are not immediately available so that the information can be transmitted once the connection becomes available.

MotoHawk Compatibility

Works well with standard MotoHawk (previously MotoTron) line of controllers and provides easy means to integrate CAN software developed using MotoHawk.

CAN Vehicle Network Interface

Captures Key platform data on J1939, J1979 or J1708 protocols without peripheral system support. Delivers processed and ready-to-use data where it is needed most: locally or remotely. Proprietary SPNs and PGNs are also supported in a J1939 environment. This can be very useful in a hybrid or EV application where all the PGNs needed might not be listed in the J1939 standard. Also the sampling rate of picking messages off the bus can easily handle up to 20 messages fro the bus at 10Hz.

GPS Receiver

Correlated vehicle data with location and positioning for enhanced logistics and fleet management.

Auxiliary Digital and Analog Inputs

Multiple auxiliary inputs to be mapped to digital or analog I/O.

Event Sensitive Triggering and Data Storage

Scripting provides user customizable data aggregation, histograms, linear and circular buffering, data analysis and device control. Compact Flash and Secure Digital (SD) sockets included for data storage.

Sensing capabilities

3-axis motion sensing with built-in shock event detection through accelerometer, external temperature monitoring when used in conjunction with external I/O connector, optional Gyro for Roll, Pitch, Yaw rates measurement, optional digital microphone to record digital audio on-board or remotely.

Wi-Fi/Cellular Telematics Module

Enables Telematics and/or PC Connectivity via LAN (Local Area Network) or available cellular communication providers allowing connectivity for off-platform enterprise communication. You can select how often you want the information sent over Cellular up to several times a minute. However, the more often that you send data the more data plan will cost.

Digital Microphone and Audio Codec

Records digital audio on board or remotely. Used in noise and vibration analysis, brake squeal, etc. The Audio Codec encodes analog audio as digital signals and decodes digital back into analog.

Technical Data

- Dimensions-153mm (6.03 in) wide x 135mm (5.30 in) long x 47 mm (1.85 in) high

- Weight-260g (0.57 lbs), core model configuration

- Wide Power Supply Input Range-Compatible with virtually all vehicle platforms including commercial and military

- Standard Temperature Range--40˚ to +85˚ C for standard features; some options have more restricted temperature ranges.

- Current Consumption-99 mA at 12 V typical (up to 171 mA when Wi-Fi and LEDs active), 55 mA at 24V typical (up to 87 mA when Wi-Fi and LEDs active), Low power sleep modes

- Multi Layer PCB-With dedicated ground plane

- Enclosure-Rugged industrial standard enclosure designed to withstand harsh environments, environmentally sealed to protect against moisture and chemical intrusion

- Mounting-Four-side flange mounting holes

- XML reporting-Enhanced data dissemination & integration: web-site based or via third party/customer enterprise systems

E600 Telematics Board

The E600 is a rugged telematics module suitable for developing a wide variety of applications. With 2 can channels and a selection of digital / analogue inputs and outputs, the E600 module is suitable for deep integration into vehicle networks.

Specifications

- 26 Pin Controller

- Microprocessor: Freescale MPC557E

- Modem: Cinterion TC63i. Jamming & disconnect detection capable

- Communications: 2 CAN channels (1 with wake-up)

- Audio: Microphone input and speaker output

- Dimensions: 155 x 145 x 33mm (6.10 x 5.72 x 1.3in)

- Memory: 1.5MB Flash, 80KB RAM, 32MB serial data flash

- Operating Voltage: 6 to 26 volts

- Operating Temperature: -40 °C to +85 °C

- Quiescent Current: <1mA

- GPS Ublox LEA-55

- up to 6 x Analogue inputs

- 4 x Digital inputs

- 1 x Analogue PSU

- 3 x 500mA Half bridges

- Optional 3.7Wh Li-Polymer battery

- E-Mark certified

Datasheet

Webstore

E600

Data/Web Service

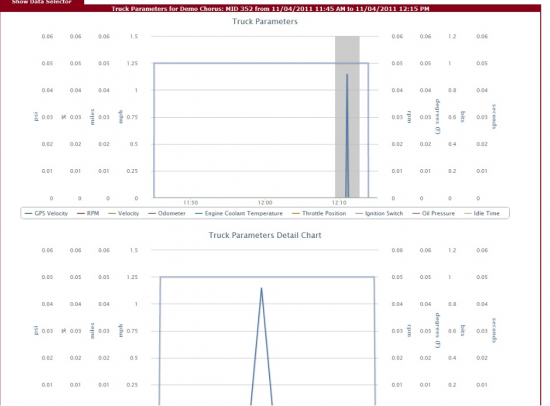

The Web Portal is a configurable vehicle and fleet monitoring portal with real-time and historical access to your vehicle data. Providing you with broad and deep visibility into vehicle conditions translates into improved operational efficiency, performance optimization and cost savings. As the gateway for the wealth of onboard data gathered by the Telematics board, the Data/Web Service provides flexible alerting capabilities through an intuitive interface allowing user-defined condition and threshold based alerts. The Data/Web Service presents real-time and historical dashboard views and reporting functionality of all vehicle data for any asset within your fleet.

Features include:

- Vehicle and fleet monitor

- Intuitive interface

- Historical information access

- Digital Dashboard

- Configurable, customized reports

- Configurable, custom alerts via Email and SMS text

- Open interchange formats: XML, CSV

- Stored in SQL tables

The web portal can be used for several core services such as:

- Data Service

- Alert Service

- Display Service

- Report Service

- User Management

- Fleet Management

CAN Based Data Logger

The logger utilizes standard SD cards for data storage making it easy to retrieve data for applications including Event Data Logging (EDR). This device is capable of logging at rates of 1ms, making it an ideal choice for any CAN bus environment. Built in key switch detection and keep-alive circuitry ensure clean shutdowns and proper file closures.

Features

- CAN data logging

- Easily log CAN bus data to an SD card

- Utilize configuration files to limit desired data or change CAN bus speed

- Data logging is limited only by the size of the SD card, right now 16GB cards are the largest supported.

- Real-time clock with battery backup providing date/time information for log files

- Firmware updates via SD Card

- Optional key switch detection

- Optional Configurable warning horn

- Status LED’s

- State of Health

- SD Card Presence and data logging

- Indicators for CAN Tx/Rx Traffic and Bus errors

- The log file is a text file format that lists all the CAN messages. This allows the user to import the data into excel or other programs.

FAQs

SD Cards

The data logger should be able to work with most SD cards. However, to help customers a selection of SD cards has been tested and verified to work. This list will be added to as more cards are tested. If you find a card that works well, let us know and we can test and add it to the list. The current approved SD cards are:

- Walgreens SD – Class 2 – 2GB

- SanDisk SD Card – Class 2 – 2GB

- SanDisk SDHC – Class 4 – 4GB

- SanDisk Ultra HCI – Class 6 – 4GB

- PNY HC – Class 10 – 8GB

- This PNY SD card has had the best results in testing, and is the recommended SD card for best results.

- SanDisk Ultra HCII – Class 4 – 8GB

- SanDisk Extreem HD HCI – Class 10 – 8GB

- SanDisk Extreem SDHC – Class 10 – 16GB

Log File Name

The log file name needs to be LOGGER.MEC with all caps. Other names might load and work with the logger. However, the logger software might not pick up other names.

Auto Flush

A new auto flush feature has been added. This feature has the data logger back up the CAN information more often to the SD card. This means that data will be on the card if power is lost. If the option is not selected the SD card will back up, but not as often meaning data will be lost. The downside to the auto flush feature is that it lowers the performance of the data logger, so it cannot log as many messages.

Extending User Action Button

The digital input is used to extend the user action button. When the input the unit will act as if the user action has been pressed. This allows you to use the action button when the data logger is installed elsewhere in the system.

Voltage Spikes Above Operating Range

The unit is load dump protected up to 60v, though when the voltage rises above 33v the unit will shut down. Therefore during transients like these the unit will be non-operational and self-recover when the input voltage returns to within specification.

How to Log Data

Logging data for the unit is very easy and straight forward, and involves setting up a short configuration file. This just takes a couple lines for the header and then a list of all the CAN messages you want to monitor. There are a couple of advanced fault options, but those are easy to use as well. You delete all files on the SD card and load the configuration file so it is the only file on the card. Next insert the SD card into the unit. The unit then has 8 LEDs and an action button. The datasheet tells you what each LED means, they include if CAN messaging is active on the bus, if the unit is recording, is there a fault, etc. The action button allows you to pause the data reading and to signal events to place a marker to be looked at.

When you are done pull the card out and plug it into the computer. There is a simple text file with all the CAN messages listed. This text file is formatted so that it can be imported into almost any CAN analyzing software.

There is also a free GUI that allows the user to more easily create the configuration file. That tool can be downloaded below.

Configuration File Tool

New Eagle CANLogger Configuration File Program

Software Update

The file to update the Datalogger can be downloaded here, Update File.

Datasheets

New Eagle CANLogger User Manual