Power Generation: Difference between revisions

| Line 3: | Line 3: | ||

==Control System Solutions== | ==Control System Solutions== | ||

===Dual Fuel Diesel Engines=== | ===Dual-Fuel Diesel Engines=== | ||

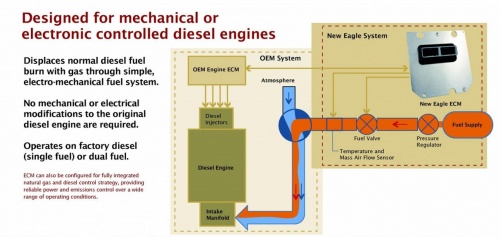

New Eagle has experience with dual-fuel and dedicated gaseous fuel engine operation for power generation. The MotoHawk ECUs were specified by Woodward for their mobile and stationary gaseous fuel systems. The parts with the MotoHawk programming tool are available from prototype to production applications. | New Eagle has experience with dual-fuel and dedicated gaseous fuel engine operation for power generation. The MotoHawk ECUs were specified by Woodward for their mobile and stationary gaseous fuel systems. The parts with the MotoHawk programming tool are available from prototype to production applications. | ||

Revision as of 14:55, 7 March 2023

Overview

New Eagle Engineering takes pride in the diversity of skill sets and achievements that its engineers bring to the team. Coming from a range of disciplines, some of us have had extensive exposure to alternative fuel technologies like fuel cell reformers, gaseous fuels like CNG, LPG/Propane and hydrogen. Such an interdisciplinary mix of people ensures a complete understanding of the systems they work with.

Control System Solutions

Dual-Fuel Diesel Engines

New Eagle has experience with dual-fuel and dedicated gaseous fuel engine operation for power generation. The MotoHawk ECUs were specified by Woodward for their mobile and stationary gaseous fuel systems. The parts with the MotoHawk programming tool are available from prototype to production applications.

Generator Start-Stop Control

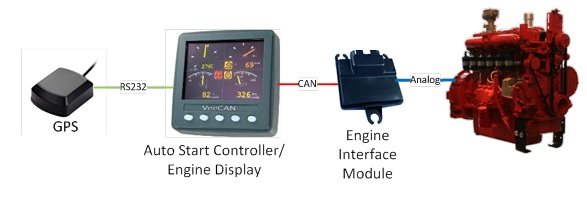

New Eagle uses a combination of GPS technology and our experience with display units to provide a rich user experience for controlling the auto-start and stop operation of the engine. Through the display unit, the user can program all aspects of the auto-start operation including operational limits which can trigger a shutdown of the engine if it is operated outside of the standard parameters.

Generator Display Controls

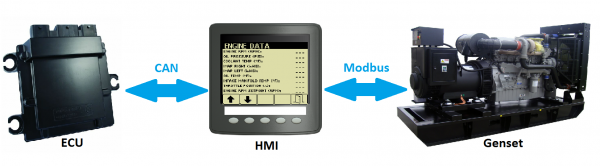

New Eagle has experience in using a display to act as a Human Machine Interface module to view and tune system parameters, as well as to act as a data relay between the ECU and the engine-generator. New Eagle can use multiple communication protocols including CAN and Modbus.

Integrated Engine Management System

New Eagle has extensive experience in engine management. Our control systems have allowed for calibration of hundreds of variables including engine mode, fault calibrations, governor calibrations, spark control calibrations, starting routine and throttle calibrations, sensor and potentiometer calibrations, and more. New Eagle's design also allows for easy reprogramming and use of the Human Machine Interface.

Wind Power Systems

As wind systems become increasingly popular, as well as complex, the need to enhance electronics and controls for achieving better efficiencies would always drive the technology forward and, at the same time, present more challenges. New Eagle's team can provide your wind-based system the right solutions from wiring, hydraulics, mechanical drives and networks to electric motor control algorithm development and power electronics such as inverter control.

Natural Gas Engine for Stationary Power

New Eagle controls engineers worked with Arrow Engine Company to develop the engine controls for a stationary power generation engine that runs on natural gas. The controls are adjustable to variable fuel energy content through a human machine interface.