ECM-5554-112: Difference between revisions

| Line 36: | Line 36: | ||

===Targets=== | ===Targets=== | ||

The PCM112-14 has different | The PCM112-14 has different targets for the main and the S12G auxiliary processor as shown below: | ||

Main Processor | |||

:1751-6685: Target ECM-5644A-112-064-1400 | |||

Auxiliary Processor | |||

:Target ECM-S12G-112-063-1400 PROD Only | |||

===Known Data Sheet Errata=== | ===Known Data Sheet Errata=== | ||

Revision as of 16:47, 15 March 2023

Overview

Product Summary

This is a high-end control module family capable of operating in harsh automotive, marine and off-highway applications. The family and its connector system are environmentally sealed and suitable for engine mounting in many applications. Each controller is available in 'F' (flash) or 'C' (calibratable) versions. Flash modules are typically used for production purposes, while calibratable modules are typically for prototyping/development only and can be calibrated in real time using MotoTune.

These modules are based on Freescale MPC5553 or 5554 processors running at 80 MHz. The 112-pin modules offer a full complement of memory storage, 3 CAN channels, and many digital and analog I/O including frequency, crank position, DSP knock detection and EGO oxygen sensor inputs. Typical applications include EV/HEV dupervisory control and full OBD2 8-cylinder sequential engines.

Features include:

- Motorola MPC5554, 80MHz Microprocessor

- Operating voltage: 9-16VDC, 24V (Jump start), 4.5V (Crank)

- Operating temperatures ranging from -40°C to 105°C

- ECU weight: 0.82 kg (1.8 lbs.)

Family includes:

- ECM-5554-112-0902

- ECM-5554-112-0904

Datasheets

ECM-5554-112-0902

- Please contact sales

ECM-5554-112-0904

ECM-5644-112-064-1400-C

GCM-5554-112-1001-C/F

Targets

The PCM112-14 has different targets for the main and the S12G auxiliary processor as shown below:

Main Processor

- 1751-6685: Target ECM-5644A-112-064-1400

Auxiliary Processor

- Target ECM-S12G-112-063-1400 PROD Only

Known Data Sheet Errata

In the ECM-5554-112 Family of Controllers Datasheet, the block Diagram of ECM-5554-112-0902(page 4) has C-H4 and C-G4 switched around:

C-G4 goes with HBRIDGE1A and C-H4 goes with HBRIDGE1B.

In the ECM-5554-112 Family of Controllers Datasheet, there is a error on page 12 that lists the pin B-C3 twice.

AN18M is labled as B-C3 and it should be B-C4.

3D CAD Data

Part Number Decoder Ring

- ECM-5554-112-0902-kD: PCM0902 module with knock development interface, DV release hardware

- ECM-5554-112-0902-kP: PCM0902 module with knock development interface, PV release hardware

- ECM-5554-112-0902-xD: PCM0902 module, DV release hardware

- ECM-5554-112-0902-xP: PCM0902 module, PV release hardware

- Use this target for ECM-5554-112-0902-F00 ("PROD") and ECM-5554-112-0902-CP0 ("DEV") modules.

- ECM-5554-112-0904-xD: PCM0904 module, DV and PV release hardware

- Use this target for ECM-5554-112-0904-F00 ("PROD") and ECM-5554-112-0904-CP0 ("DEV") modules

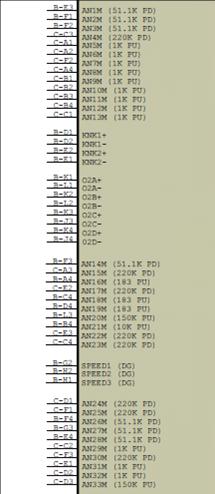

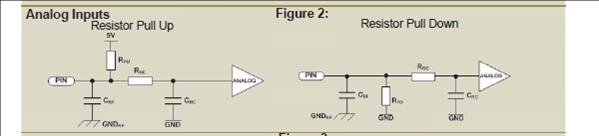

Pull-up and/or Pull-down on the Analog Inputs of the 5554-112

ECM5554-112 E-Stop

A problem was reported that the Fuel Pump Relay Driver (FUELPR) was not being disabled after a STOP assertion (pinout B-H3). Woodward confirmed the issue and came up with a solution. The correction was completed in the 2010a Beta 5 release. There are open trackers to apply the change in MH2009a and 2009b.

ECM5554-112 RoHS or ELV Compliance

The PCM0904 is compliant to the current ELV (End-of-Life Vehicle Directive) requirements, not RoHS. Note, RoHS applies to consumer electronics products, and ELV is still the applicable directive for automotive parts. Again, this module is fully compliant to ELV and can be sold in Europe.

ELV Compliant End of Life Vehicles (ELV) Directive 2000/53/EC requires that certain automotive products be free (except for trace impurities) of mercury, cadmium and lead as of 2003-7-1. Lead can still be used as an alloying additive in copper, steel and aluminum and in solderable applications. These products comply with the ELV directive.

EU RoHS Compliant Restrictions on Certain Hazardous Substances (EU RoHS) Directive 2002/95/EC requires that certain electrical and electronic products be free (except for trace impurities) of mercury, cadmium, hexavalent chromium, PBB, PBDE and lead as of 2006-7-1. Certain exemptions are allowed such as lead used as an alloying additive in copper, steel and aluminum. These products comply with the EU RoHS directive. These products also comply with the ELV directive. Note that as of July 1, 2008 products that are shown as RoHS compliant do not contain decabromodiphenyl ether.

General Purpose Use of Knock pins

The knock sensor pins are dedicated, and have no alternate purpose other than Knock detection. One exception is that this circuitry is known to be used as a hardware "notch" filter.

Powering the ECM-5554-112-0904 (PCM0904)

The 112-pin modules are nominal 12-volt:

- VBATT (min) = 4.5 volts (crank transient) and 6.3 V (continuous).

- VBATT (normal) = 9-16 volts.

This voltage is expected at the BATT, BATT2, KEYSW, DRVG1, DRVG2, fuel injector, H-bridge, low-side drivers.

Specifics:

High Voltage Operation The following voltages are to be measured at the BATT pin, referenced to the PWRGND pins. Jump Start. The module shall operate normally when exposed to 24 volts for 5 minutes at an ambient temperature of 23 degrees Celsius.

Reverse Battery Connection

The module shall not be damaged by 5 minutes of reverse battery (-12 volts). This is a system level test and assumes a correct harness is in use. Specifically, it is assumed that the main power relay will be off.

Abnormal Connections

The module shall not be damaged from short-to-ground, short-to-battery, or intermittent open-circuit faults on any I/O signal. The following signals are excluded from this requirement since they are inherently a short circuit:

- PWRGND (not protected from short to battery).

- DRVP (not protected from short to ground).

- XDRG (not protected from short to battery).

- GNDREF (not protected from short to battery).

Note: For purposes of test, it may be assumed that DRVP is applied to the system prior and during the abnormal connection test.

Frequency (Speed) Inputs Notes

SPEED1 (B-G2), SPEED2 (B-H2), SPEED3 (B-H1) logic thresholds and hysteresis are hardware configurable. However, this option is not available in MotoHawk, but might be added in the future.

SPEED1 - This input is normally used to resolve a variable frequency digital speed signal. Software will be capable of selecting either a high impedance mode for 0 to 5 volt sensors or a 1 kilo-ohm pullup to 5 volts for open-drain type sensors, however this option is not available on present versions of MotoHawk. The default value is 1K, when not software selected.

SPEED2 and 3 - This input is normally used to resolve a variable frequency digital speed signal. The sensor shall provide a 0 to 5 volt signal. Note, the sensor is expected to be a low-side driver with internal pull-up to 5 volts of ~ 4.7 k-ohms.

Note: The SPEED1, CAM, and CNK inputs have the hardware ability on the 112 controllers to select a pull-up resistor. The block Passive Pull Strenght was added in 2011a to choose this option; however, only the Crank_DG presently has that ability. It is planned to add this functionality for the CAM and SPEED1 inputs, probably in 2012a MotoHawk.

Differences between the 0902 and 0904

Here is the full list of changes from PCM0902 to PCM0904.

1) Remove the H1 H-Bridge and replace with two Infineon BTN7930 ½ Bridge devices.

2) Remove the H2 H-Bridge and replace with two Infineon BTN7930 ½ Bridge devices.

3) Remove the On Semi NIF5002 Injector Drivers and replace with the On Semi NCV8403.

4) Remove the TACHLINK transistor (PZT3904) and replace with BFN38 device.

5) Routing of case ground traces to pin B-C3 (replaces CAN2 shield pin).

The new H-Bridges are more capable than the older parts and can be run at up to 10A depending on total ECU power dissipation. The injector driver change allows the option to run 2 injectors per driver (2A max) but again power dissipation must be considered. The TACHLINK change was to address robustness to transients.

An interesting point to be noted while using 0902 modules is that while trying to work with the Motohawk H-bridge output block, the resource allocation might show 'None'. It is because that block is not exposed to the H-bridge pins in the 0902 controller. In this case, using the Motohawk PWM block can give you exact same results with the correct resources on the 0902 module.

CAN Shielding Differences Between 0902 and 0904

For ECM-5554-112-0902 (PCM0902): CAN_1 is not shielded, not internally terminated. CAN_2 is shielded, not internally terminated. CAN_3 is shielded, internally terminated 120-ohm.

CANSHIELD2 and CANSHIELD3 are available for shielded bus connections on the respective busses. The internal connection to the PCM ground consists of a 1 ohm resistor in series with a 10 nano-farad capacitor (i.e. no dc path). CAN shielding is not always standardized and this implementation may or may not be appropriate for any specific application.

For ECM-5554-112-0904 (PCM0904):

CAN_1 is not shielded, not internally terminated.

CAN_2 is not shielded, not internally terminated.

CAN_3 is shielded, internally terminated 120-ohm.

CANSHIELD3 is available for shielded bus connections. The internal connection to the PCM ground consists of a 1 ohm resistor in series with a 1 micro-farad capacitor (i.e. no dc path). CAN shielding is not always standardized and this implementation may or may not be appropriate for any specific application.

For the PCM0904 model, pin B-C3 was changed from CAN2 SHIELD to CASEGND. For typical applications, the CASEGND pin should be left not-connected.

Note the change in capacitor value for the shield between PCM0902 and PCM0904.

CAN Transceiver Notes

The 112 pin module uses an Infineon TLE 6250G transceiver. TLE 6250 is a high speed transceiver with the following features:

- CAN data transmission rate up to 1 MBaud

- Receive-only Mode and Stand-by Mode

- Suitable for 12 V and 24 V applications

- Excellent EMC performance (very high immunity and very low emission)

- Version for 5 V and 3.3 V microcontrollers

- Bus pins are short circuit proof to ground and battery voltage

- Overtemperature protection

- RoHS compliant

- AEC Qualified

The RF capacitors are 100pF and there is a Zener set for transient protection.

0904 Models without XDRP1 Capacitor

Difference between VP9DVU12A650-AA and VP9DVU-12A650-AB

VP9DVU-12A650-AA lacks a 10nF ESD capacitor on the XDRP1 (5V sensor supply) at J1C-D4. The lack of this capacitor leaves the module susceptible to radiated noise coupled onto the application harness. The coupled noise can cause instability in the XDRP1 voltage supply or module resets. Vehicle EMC issues were experienced during Free Field testing at approximately 23V/m and 140-180MHz.

To avoid the issue, the XDRP1 output should be disconnected from the wiring harness. If the XDRP1 output is required, a ferrite choke can be used to filter the noise. Placing a FairRite 43 material solid ferrite or Steward 28 clamp ferrite on the harness wire leading to XDRP1 within one inch of the mating connector will resolve the issue.

VP9DVU-12A650-AB incorporates a very small change to the PWB connecting a 10nF capacitor to the XDRP1 J1 pin making the module immune to radiated and coupled noise.

What is the LSO output interface?

LSO6 & 7 are designed for O2 heater control, and they make a nice general purpose low side drive. The FET’s are controlled via an MC33800 pre-driver. The drive IC data sheet, a Freescale MC33800, is found at MC33800 driver. In addition, there is a 10 nF cap on the input for ESD.

What is the nominal current draw of the ECM-5554-112?

Minimum 'on' current is typically not specified as this is not usually a concern since the engine (and alternator) are running. The current draw is really application dependent as the MPR may or may not be on, and any sensors connected will draw current. Looking at a couple production (PROD or FLASH) units, 300mA is the draw without any sensors or loads connected.

Analog Inputs

According to Woodward and the ECM-5554-112-0904 module schematic, the following inputs are connected to the VISTA chip instead of the MPC5554 processor's integrated ADC.

- AN12

- AN13

- AN18

- AN19

- AN20

- AN31

- AN32

- AN33

It is not uncommon to get some extra ADC noise for the pins connected to the VISTA chip, and we have surmised that ADC counts to temperature calculation logic tends to magnify this variation. We recommend that these inputs only be used for sensors that can tolerate that range of variation.

Also the AN32 and AN33 inputs have a selectable reference (not exposed in MotoHawk). Prior to MotoHawk 2010b they had been set to use a 1.6V reference. 2010b and on use a 5V reference. So for MotoHawk 2010A and older you need to use an extension file to set the reference voltage to 5V.

Analog Input Resolution

The ECM-5554-112 module has 12 bit resolution for the analog inputs, instead of the 10 bit available on the other MotoHawk ECUs. To get the 12 bit resolution you need to assign it in the Analog Input block.

Speed Inputs = Hall Effect

Speed1, Speed2, and Speed3 are Hall Effect type inputs

XDRP Current Capability

As mentioned on the datasheet, the independent current capability of XDRP1 is 50 mA and that of XDRP2 is 100 mA. In other words, each of them is connected to a separate pin on the power supply chip. Further, the same voltage (XDRP1 or 2)is used to reference pulled up AN inputs.

Key-Off Timer

The 0904 module has a Key-Off Timer feature which can keep track of the time its keyed OFF. This may be used with additional logic to create a clock output in some applications.

Boot Key Recovery

We have found that the 112 pin modules tend to be faster in booting up than the boot key. So when recovering this module with a boot key, it may help to apply power to the boot key first and the module a few seconds afterwards. For instance, turn the power supply on with the module unplugged, start MotoTune programming, then plug the ECU into the junction box a few seconds later. The CAN baud rate must be set to 250kbps during boot key recovery.

Measuring Current From the Hbridge

In Simulink you can request to read a current output from the Hbridge driver. The current is read from the driver chip across a sense resistor and "delivers a current proportional to the forward load current flowing through the active high side switch". The current is directly measured from the pin. So, the current measured would be affected by the load characteristics combined with the parallel sense resistor. Also, if the PWM block is outputting a frequency, instead of being in steady state, then the meter may be giving a calculated RMS current which would differ by a constant multiplier. If the high side switch is inactive or the current is flowing in the reverse direction no current will be driven except for a marginal leakage current.

Low Voltage Operation

The data sheet says the 112 module works 9-16 volt. It is actually designed to run at 6.3V continuous. It has been known to work at a "bit less", but this is not guaranteed on every unit.

9V is the min ‘normal’ range. 6.3V is the min without reset (during cranking) but the system will not be able to operate at that voltage since relays will not close and some IC’s will fault for low battery voltage.

Webstore

Webstore: Motohawk Engine Control Modules