Engine and Transmission Controls: Difference between revisions

No edit summary |

|||

| Line 25: | Line 25: | ||

The New Eagle Engine Management Control System uses MotoHawk model-based developed tools, process, and libraries. This is carried through from prototype through production. New Eagle has utilized the basic building blocks provided in this tool to create a set of high level function libraries, which can be used to construct a complete powertrain management system to customer specifications. | The New Eagle Engine Management Control System uses MotoHawk model-based developed tools, process, and libraries. This is carried through from prototype through production. New Eagle has utilized the basic building blocks provided in this tool to create a set of high level function libraries, which can be used to construct a complete powertrain management system to customer specifications. | ||

[[image:Ipc.JPG| | [[image:Ipc.JPG|thumb|1000px]] | ||

====Engine Control Library Blocks ==== | ====Engine Control Library Blocks ==== | ||

Revision as of 19:22, 29 March 2012

Engine Management Systems

New Eagle engineers offer system engineering and customers embedded control systems solutions including system designs, development, and integration tools and processes. Services that are provided by New Eagle include controls, production software testing, component and hardware selection and development, user interface devices, and long term customer support.

Experience

New Eagle has the following experience:

- Powertrain and vehicle modeling

- Engine calibration

- Model based controls development methods

- Engine control algorithm development including port and direct injected fuel delivery, spark advance, bypass air, torque management, electronic throttle positioning, cylinder deactivation, cam phaser positioning, and all associated diagnostics.

- Interactive transmission controls for conventional automatic transmissions, CVT, and DCTs

- Extensive experience working to OEM production requirements, and utilizing industry best practice development methods and processes.

- Experience working in partnership with Tier 1 suppliers, both domestically and internationally.

- Supplier development, evaluation, and selection

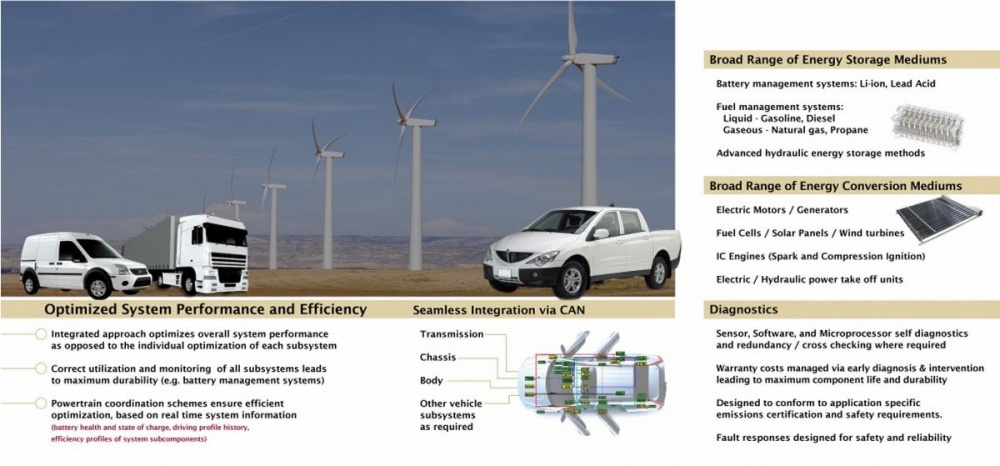

Integrated Powertrain Control

The New Eagle Engine Management Control System uses MotoHawk model-based developed tools, process, and libraries. This is carried through from prototype through production. New Eagle has utilized the basic building blocks provided in this tool to create a set of high level function libraries, which can be used to construct a complete powertrain management system to customer specifications.

Engine Control Library Blocks

The high level building blocks in the New Eagle function library are shown below, along with a brief description of the functionality contained within:

Sensors The hardware interface to all sensors, including resource assignments and basic ADC to engineering units conversions are performed here. Functions in this block include:

- analog inputs (pressures, temperatures, voltages, positions, flow rates, switch states, etc.)

- CAN inputs (same as above, but via CAN interface)

Actuators The hardware interface to all actuators, including resource assignments and basic scaling to ADC units are performed here. Functions in this block include:

- primary actuators (spark plugs, throttle body, fuel injectors, fuel pumps, "hardwired" lamps, etc.)

- secondary actuators / accessories (alternator, fan , AC compressor, etc.)

Virtual Sensors Within this block are the modeled sensors. The modeled sensors are state variables that have been created from available actual sensor information. This modeled sensor information is available to the higher level control algorithms. Examples of functionality contained within this block include:

- modeled air charge

- engine running timers

- engine state determination (cranking, running, stall, etc.)

- steady state determination

- modeled temperatures

- Lambda (wide range O2 and switch type sensors)

Diagnostics Sensors Overrides This block provides a means of replacing the sensor value with a default value when the diagnostic algorithms deem it appropriate, based on the severity of the fault that has been identified.

Base Algorithm controller This block contains the core high level functionality of the control system. It contains most of the functions required for basic engine operation. Some examples of functions contained within this block include:

- Pedal Interpretation as a torque requestor

- Cruise Control

- PTO Control

- Torque limiting functions (over-speed, over-rev, interface to transmission limiting requests, and ABS limiting requests)

- Torque arbitration

- open loop fuel control

- closed loop fuel control

- Upstream control (wide-band and switch type control available)

- Downstream control (switch type control only)

- intake airflow characterizations and dynamics

- idle control (utilizing slow and fast path torque actuators)

- Deceleration Fuel Cutoff and safety fuel cut (DFCO/FC)

- ignition angle and energy characterization as a function of speed, load, temperatures, pressures, knock, etc.

- engine torque characterization – forward path (friction and pumping losses, indicated engine torque to air charge characterization, modifiers for ignition retard from MBT as scheduled from base spark control, temperature and pressure modifiers, equivalence ratio modifier, ignition angle offset request based on fast path torque, torque reserve request and slow path / fast path coordination, DFCO/FC)

- engine torque characterization – reverse path (frictional and pumping losses, air charge to torque characterization, modifiers for ignition retard from MBT, equivalence ratio modifier, temperature and pressure modifiers, DFCO/FC).

- accessory control (fan, AC, alternator, etc.)

Component Control This block contains control algorithms linked to specific actuator hardware. functions contained within this block include:

- throttle position controller

- throttle learning algorithm

- ice breaking algorithm

- certain customer specific actuators

- HEGO heater control

Diagnostics Actuators Overrides This block provides a means of replacing the commanded value with a default value when the diagnostic algorithms deem it appropriate, based on the severity of the fault that has been identified.

Characterization This block provides conversions from engineering units to the hardware level units

- fuel mass to injector pulse width conversion (with appropriate temperature, pressure, voltage corrections)

- ignition angle and spark energy to ignition coil start and stop angles

Drive By Wire Redundant Calculations and Diagnostics This block contains all of the functionality required to validate all inputs and calculations resulting in the positioning of the throttle blade. These functions include:

- sensor rationalities with redundant and modeled sensors

- torque path calculations with redundant sensor set

- main micro checking with secondary checking micro (cross checking by each micro to monitor the state of health of the other micro)

- 3 level torque safety structure

OBD II Diagnostics OBD blockset integration aiming to be compliant with OBD II 1968.2

- Sensors: input high, input low, rate high, rate low

- Actuators: open/shorted

- CAN inputs: rate

OBD II Major Monitors and Rationalities This block contains the major monitors and rationalities. Examples of functions contained within this block include:

- fuel system monitor

- catalyst monitor

- simple misfire

- catalyst temperature model (utilized by the catalyst monitor and certain base algorithm functions).

- engine coolant temperature monitor

Communications and Reporting This block includes the interfaces required for J1939 communications, freeze frames, etc. as required for diagnostics tools and customer specific tools such as "in-plant" and "end of line". Communications interfaces to other systems are also provided, such as:

- cluster

- body controller

- transmission controller

- chassis controller

- CCP support

Standard Engine Controller

New Eagle offers a pre-programmed, tunable engine controller Standard Engine Controller

Gasoline/Gaseous & Diesel Fuels

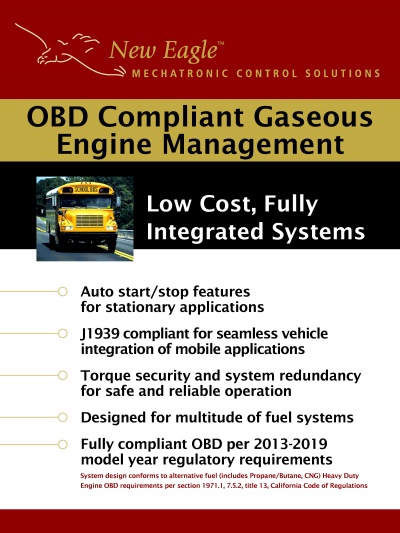

Gaseous Fueled Engine Controls

- Automotive quality and prices for components including sensors, throttles, and engine controllers

- Enhanced user interface for engine control and system installation and setup

- Auto Start / Stop features for scheduled duty cycle or remote engine and load control

- Fuel efficiency advantages by utilizing automotive style torque control algorithms

- OBD diagnostics to protect engine and other system components

- Adaptive to multiple fuel usage

- Adaptable controls for mobile and stationary applications

- Experience with vapor lock handling and purge routines

OBD Diagnostics

- Reduces service time from trouble shooting

- Protects engine from harmful conditions such as low oil

- Reduces engine and system component warranty costs through system protections

- Prognostics available for scheduled service intervals

- Remote communications for system status available

- Ability to meet and exceed emissions requirements based on application

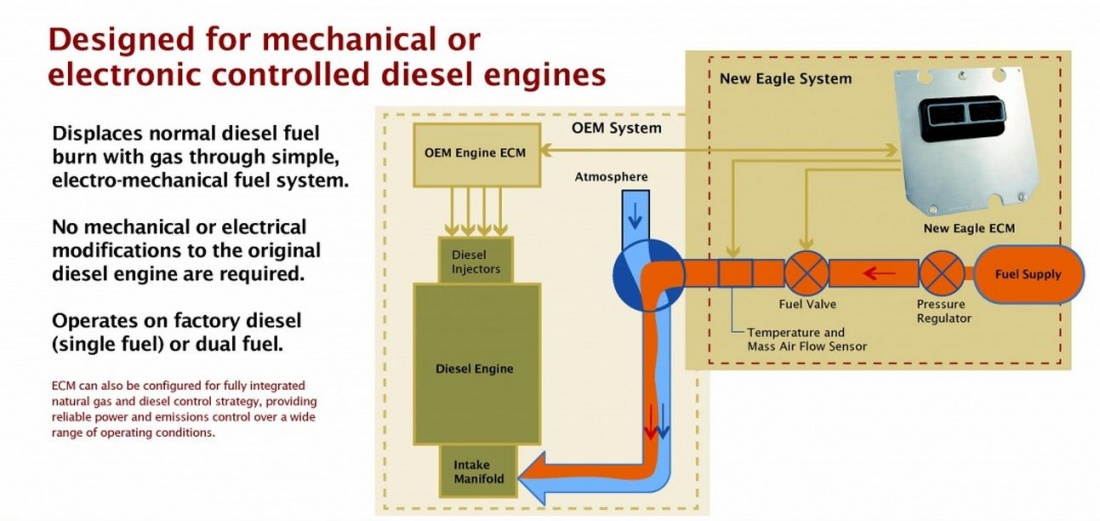

Dual Fuel Systems

New Eagle engineers have worked to help customers build Dual-fuel (diesel / cng) control systems to reduce the fuel cost of stationary and mobile applications, both certified and non-certified. The MotoHawk tool chain is an ideal product for such an application.

- Allow existing diesel engines to safely substitute natural gas ranging from 65% to 80%

- Mileage dramatically increases due to burn rate and efficiency of diesel combustion

- Market payback: occurs within months, depending upon price of fuel

- Seamless integration with existing vehicle systems via CAN:

- Transmission

- Chassis

- Body

- Instrument Clusters

Transmission and Driveline

New Eagle’s team of engineers has had vast experience in the development, integration and deployment of controls. With past experience - including and not limited to: Torque based Control, Chassis Powertrain Controls, Active Braking, ESP Stability, interaction based on Torque messaging, Powertrain coordination schemes optimization and more, for both diesel and gasoline engines - New Eagle, as Controls Integrators, seeks to accomplish even more challenging projects in future. We believe we have the correct solution to meet the needs of all our customers, whether it is a specific demand or a simpler challenge. Not only that, our experience over the years has given us the capabilities to ensure success with high quality of reliability, robustness, performance and support for our projects.

Emissions Controls

Ignition Driver

New Eagle offers the Woodward ignition driver, part number IGN-DRVR-001-01 / 3522-1026. Here is a pinout and description of the connectors:

-

Ignition driver pinout

-

Ignition driver connectors

The connectors are:

- Delphi Metri-Pack 150.2 female, 2 pin (CON-FEML-011A-00)

- Delphi Metri-Pack 150.2 female, 4 pin (CON-FEML-011C-01)

- Delphi connector terminals (CON-TMFL-IGNDRV-00)