OBD Compliant LPG Engine Conversion: Difference between revisions

No edit summary |

No edit summary |

||

| Line 9: | Line 9: | ||

New Eagle developed the control system on a liquified petroleum gas engine for [http://powertrainintegration.com/ Powertrain Integration]. The system used the [http://en.wikipedia.org/wiki/GM_LS_engine General Motors LS3 Engine], but substituted a LPG fuel system for the traditional gasoline fuel system. New Eagle provided torque security for electronic throttle control. | New Eagle developed the control system on a liquified petroleum gas engine for [http://powertrainintegration.com/ Powertrain Integration]. The system used the [http://en.wikipedia.org/wiki/GM_LS_engine General Motors LS3 Engine], but substituted a LPG fuel system for the traditional gasoline fuel system. New Eagle provided torque security for electronic throttle control. | ||

New eagle also implemented purge and evaporative emission controls for the fuel delivery system. The system is required to be OBD compliant in its classification. | |||

==Solution== | ==Solution== | ||

Revision as of 17:40, 13 July 2012

Opportunity

New Eagle developed the control system on a liquified petroleum gas engine for Powertrain Integration. The system used the General Motors LS3 Engine, but substituted a LPG fuel system for the traditional gasoline fuel system. New Eagle provided torque security for electronic throttle control.

New eagle also implemented purge and evaporative emission controls for the fuel delivery system. The system is required to be OBD compliant in its classification.

Solution

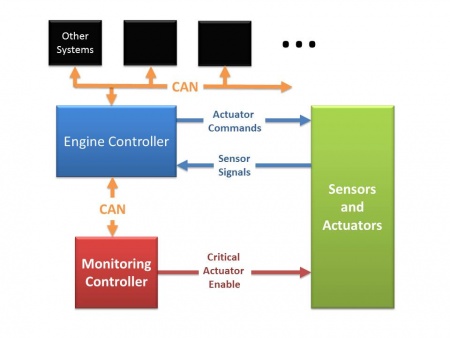

New Eagle provided the engine control module, the safety controller and the control algorithms for the engine control system system. A five phase program plan was created and tracked throughout the project. This insured that all of the critical steps (design, DFMEA, testing) for product development were completed on time. Weekly updates were provided to the customer. New Eagle worked closely with Powertrain Integration in all phases to ensure a successful program.

Hardware

Initially a ECM-0565-128-0702 Calibratible Engine Control Module was used for engine control algorithms. The team switched to a ECM-5554-112-0904 Calibratable Engine Control Module for later development. The calibratable module provides quick calibration through the MotoTune calibration tool. An ECM-5554-112-0904 flash module is scheduled for series production when the calibration parameters for OBD compliance have been finalized.

A ECM-0S12-024-0802 Calibratable Egnine Control Module was implemented for the safety processor. This controller communicates with the engine controller and ensures that it is operating properly. If the safety controller detects a discrepancy, it disables critical control actuators and shuts down the system.

Toolchain

New Eagle used the MotoHawk Toolchian from Woodward to implement the engine controls and monitoring controls. New Eagle has an extensive library of engine control algorithms and gaseous fuel algorithms that were used as a basis for this program. By using the MotoHawk tools and the base libraries, New Eagle was able to develop the LPG engine controls quickly. Using the verified controller, base software and algorithm libraries, increased the reliability and confidence of the system.

A DBC file for the engine CAN communication protocol was provided for the program. Using the New Eagle Network Toolbox Software, the team was able to quickly implement the CAN communications saving significant development time. By ensuring that both the sending and receiving module used the same DBC file, debug time was reduced.