Raptor VeeCAN

Return to the main Raptor page

Overview

The Raptor™ VeeCAN platform is a Simulink toolset for development on the VeeCAN 320 Display. Models built for VeeCAN using the Raptor framework are highly transferrable to other modules in the Raptor family. Raptor VeeCAN enables development of its graphical display and the five user action buttons. This allows for rapid development of a Human Machine Interface (HMI).

VeeCAN Libraries

For information on the blockset libraries that support VeeCAN, Go Here

Inputs and Outputs

The following is a list of the I/O on the VeeCAN:

- (2) CAN

- (1) RS-232

- (1) Tachometer Input

- (7) Analog Inputs

- 0-10VDC

- 0-2.5VDC

- 0-500mA

- (2) Digital Inputs

- (4) Digital Outputs

CAN Development

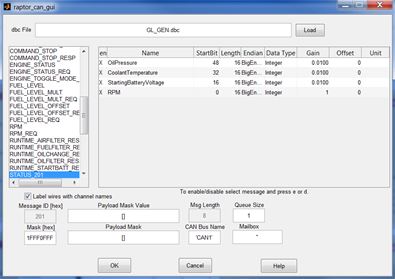

CAN development within the Raptor framework integrates industry-standard DBC files. This allows for quick sharing of a CAN protocol both within and outside the Raptor framework. The image below shows the configuration screen of a CAN Rx message block after a DBC file is selected.

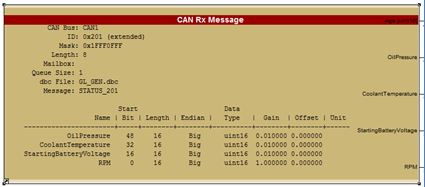

Selection of a CAN automatically populates signal output specifications on the Raptor CAN message blocks with the information contained in the DBC file, as shown in the image below.

Raptor VeeCAN Example

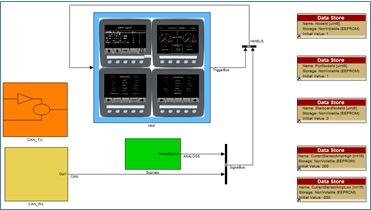

The image below is the foreground loop of a RVC project. It demonstrates separation of HMI logic from the control and signal logic This is a stylistic approach to ensure easy transferability of logic to and from other Raptor platfroms that do not have HMI functionality.

VeeCAN Display Development

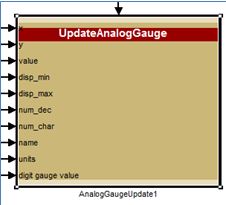

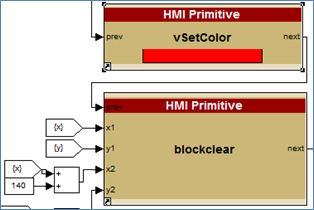

The Raptor HMI blocks were designed both to allow ease of use and to allow low-level control of display features. In the RVC library you will find high level blocks to quickly display an assortment of information and graphics, such as: lists, menus, gauges, images, and text strings. These high level blocks have been designed from a primitive block set, meaning that tweaks can be made to these under-the-covers primitives to configure the display to your taste, or to help you create your own display screens from scratch. The images below demonstrate a gauge block and a subset of the primitive blocks within it.

Simulation

The RVC simulator creates a strong link from the software development cycle to the hardware testing cycle. Typically these would be two distinct, time-consuming, phases, but, with strong coupling of the simulator and the hardware (hardware-in-the-loop simulation), and with real-time debugging, iteration time is drastically reduced.