Bench Tools

MotoHawk Control Solutions/Bench Tools

Breakout Assemblies

Performing ECM signal measurement and failure testing without modifying the harness can be difficult and time consuming. ECM breakout boxes are rugged harness inserts designed to make this painful job easy. Breakout boxes were designed by application developers to assist troubleshooting and failure mode testing activities and are a highly recommended part of every developer's toolkit. The family of breakout boxes covers the entire range of Woodward's MotoHawk Control Solutions modules. The breakout box plugs into the existing harness connectors and ECM, but also provides an extension with measurement points and circuit breaking bars. Each pin to the ECM can be probed, open circuited, or connected to any other signal. Each breakout box assembly comes with an Expander toolkit of patch cables, shorting bars, and banana jacks.

Webstore

Webstore: Breakout Box Assemblies

Connector Crimp and Removal Tools

Includes tools that are designed to strip, cut, crimp, and remove wire.

Webstore

Webstore: Connector Crimp and Removal Tools

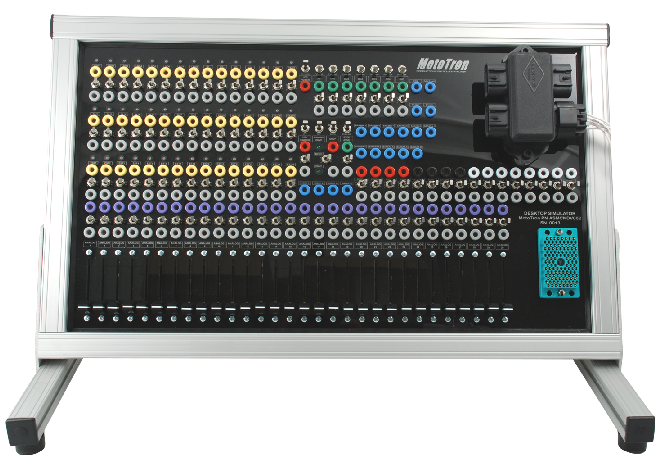

MotoHawk Desktop I/O Simulator

The MotoHawk Desktop I/O Simulator is a handy tool for bench development and testing. It allows you to adjust analog input levels with potentiometers, monitor output, test application scenarios, etc, without needing actual sensor connections. The MotoTron Control Solutions wiki has more information. If you are interested, please contact sales@neweagle.net. The part number is ASM-CNDV-002.

Webstore

Webstore: MotoHawk Desktop I/O Simulator

[[text:The Desktop I/O Simulator is designed to assist in developing control programming for a MotoHawk ECM; this practical device enables you to more easily simulate and adjust analog input levels (via onboard potentiometers), monitor output, test application scenarios, etc., without requiring the actual sensor connections. The Simulator has I/O, CAN connections, power and ground channels, keyswitch, and other features as applicable, which map to the respective resources of the ECM in use. Connect the MotoHawk ECM to the Simulator, using the appropriate available harness. Connect a computer with programming and calibration tools to the ECM via CAN or RS485 connection to the mounted CAN junction box, or floating connectors. Then use the Simulator to adjust input levels, drive output loads, monitor I/O signals, verify parameters, and as a result better understand and adjust the control programming needed, without using actual application hardware.|right]]