Bench Tools

MotoHawk Control Solutions/Bench Tools

Breakout Assemblies

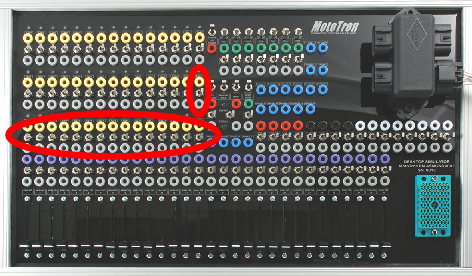

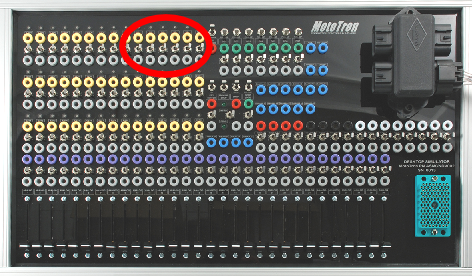

Performing ECM signal measurement and failure testing without modifying the harness can be difficult and time consuming. ECM breakout boxes are rugged harness inserts designed to make this painful job easy. Breakout boxes were designed by application developers to assist troubleshooting and failure mode testing activities and are a highly recommended part of every developer's toolkit. The family of breakout boxes covers the entire range of Woodward's MotoHawk Control Solutions modules. The breakout box plugs into the existing harness connectors and ECM, but also provides an extension with measurement points and circuit breaking bars. Each pin to the ECM can be probed, open circuited, or connected to any other signal. Each breakout box assembly comes with an Expander toolkit of patch cables, shorting bars, and banana jacks.

Webstore

Webstore: Breakout Box Assemblies

Connector Crimp and Removal Tools

Includes tools that are designed to strip, cut, crimp, and remove wire.

Webstore

Webstore: Connector Crimp and Removal Tools

MotoHawk Desktop I/O Simulator

The MotoHawk Desktop I/O Simulator is a handy tool for bench development and testing. It allows you to adjust analog input levels with potentiometers, monitor output, test application scenarios, etc, without needing actual sensor connections. The MotoTron Control Solutions wiki has more information. If you are interested, please contact sales@neweagle.net. The part number is ASM-CNDV-002.

Webstore

Webstore: MotoHawk Desktop I/O Simulator

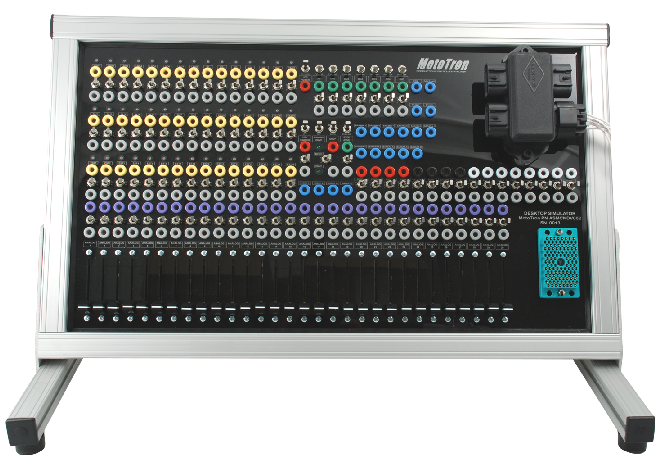

The Desktop I/O Simulator is designed to assist in developing control programming for a MotoHawk ECM; this practical device enables you to more easily simulate and adjust analog input levels (via onboard potentiometers), monitor output, test application scenarios, etc., without requiring the actual sensor connections. The Simulator has I/O, CAN connections, power and ground channels, keyswitch, and other features as applicable, which map to the respective resources of the ECM in use. Connect the MotoHawk ECM to the Simulator, using the appropriate available harness. Connect a computer with programming and calibration tools to the ECM via CAN or RS485 connection to the mounted CAN junction box, or floating connectors. Then use the Simulator to adjust input levels, drive output loads, monitor I/O signals, verify parameters, and as a result better understand and adjust the control programming needed, without using actual application hardware.

Specifications

- Aluminum frame, angle-mounted for ease of use, with scratch-free rubber feet

- Over 200 banana jacks in total for I/O - connect inputs or meters/oscilloscope to outputs

- 30 Channels of Analog Input (switchable - On / Off) with dedicated potentiometer sliders

- 45 Channels of Low or High Side Output (switchable - On / Off)

- 3 CAN Channels (switchable - On / Off)

- 1 RS485 Channel (switchable - On / Off)

- 8 Digital Inputs (switchable - On / Off or pulled High / Low)

- 10 Power and Ground Channels (switchable - On / Off) , including ECM Input Voltage+/-, XDRP, XDRG, MPRD, DRVP, DRVG, and Key Switch

- 4 Knock sensor inputs

- 4 CAM/Crank inputs

- 11 Non-assigned banana jacks

Depending on the ECM resources available, some of the jacks may not be mapped or connected to any resource from the ECM. Refer to the datasheet for your particular ECM to determine the resources available. It is best to check and verify the presence of the intended Simulator/ECM resource before attempting to apply in a test scenario.

Setup

Make the following connections:

- SCF: Plug connector labeled SCF on the back of the simulator into the 4-way junction box on the front of the simulator

- Power Cable:Plug the power supply cables on the back of the simulator into your power supply.

- CAN: Connect your CAN or communications cable (sold separately) into the Simulator 4-way Junction Box.

Optional Connections:

- SCM: Optional connector for external key switch

- Serial: Optional connector for external serial communications

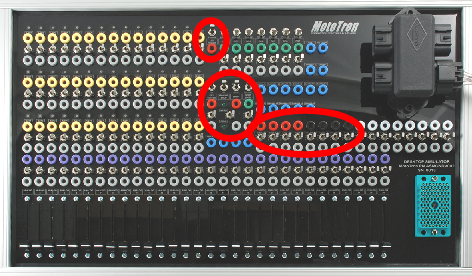

Power and Ground Channels

Warning: Simulator is configured for 12V systems. For 24V systems, the relay connected on the backside must be changed to the 24V relay or failure may occur. The Power and Ground Channels are located in the center of the Simulator, and include BATT, XDRP A/B, XDRG, MPRD, DRVP, DRVG, EST RTN, and Key Switch. These are connected to the ECM via the harness, though the jacks allow optional external connections.

Note: Connection to a 12V DC (nominal) power supply is required. The Desktop I/O Simulator has a positive and a negative connector for use with a power supply. Do not use a supply higher than 36V DC, as the LED circuits are not able to withstand this.

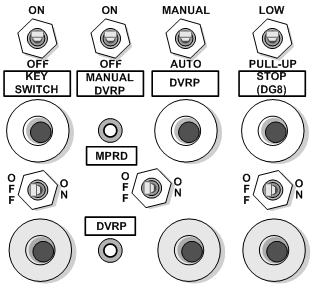

- KEY SWITCH: The KEY SWITCH interface includes a top, vertical-direction ON/OFF switch, which connects directly to the key-switch (ECUP) input to the ECM, to turn the ECM keyswitch on/off. The other, side-to-side switch enables/disables the ON/OFF function of the top switch. The red jack allows connection of an external keyswitch input. Note: Some ECMs use the key switch input, others do not. Refer to the datasheet for your ECM.

- MANUAL/DVRP: You can turn the DVRP to the ECM on/off via the MANUAL/DVRP ON/OFF switch, if the DVRP switch (below) is set to MANUAL. The other, side-to-side switch enables/disables the ON/OFF function of the top switch.

- DVRP: You can turn the MANUAL DVRP on/off via the DVRP ON/OFF switch. When the switch is OFF, the DRVP power is automatically supplied. When ON, use of the MANUAL DVRP ON/OFF switch controls the DVRP power.

- LEDs: The MPRD indicator LED is ON when MPRD power is ON (as a result of turning on the ECM). The DVRP indicator LED in ON to indicate the DVRP power to the ECM is ON.

- STOP (DG8): The STOP interface includes a top, vertical-direction LOW/PULL-UP, which connects directly to the E-STOP input to the ECM (the DG8 input acts as a STOP input on the 128 pin ECM). The other, side-to-side switch enables/disables the ON/OFF function of the top switch. The red jack allows connection of an external STOP input.

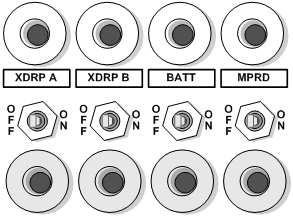

- XDRP A/B: The two XDRP jacks, A and B, each include a side-to-side ON/OFF switch, which turns the respective transducer power on/off.

- BATT: You can turn the battery power to the ECM on/off via the BATT ON/OFF switch.

- MPRD: You can turn the power to the main power relay driver on/off via the MPRD ON/OFF switch.

- LEDs (see drawing above): The MPRD indicator LED is ON when MPRD power is ON (as a result of turning on the ECM). The DVRP indicator LED in ON to indicate the DVRP power to the ECM is ON.

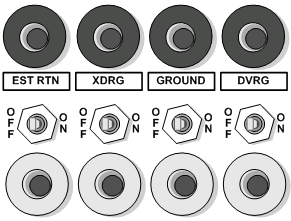

- EST RTN: The EST RTN input provides connection to the EST return resource on the connected ECM. You can connect or disconnect the EST return to the ECM via the EST RTN ON/OFF switch.

- XDRG: You can connect or disconnect the transducer ground to the ECM via the XDRG ON/OFF switch.

- GROUND: You can connect or disconnect the power ground to the ECM via the GROUND ON/OFF switch.

- DVRG: You can connect or disconnect the driver ground to the ECM via the DRVG ON/OFF switch.

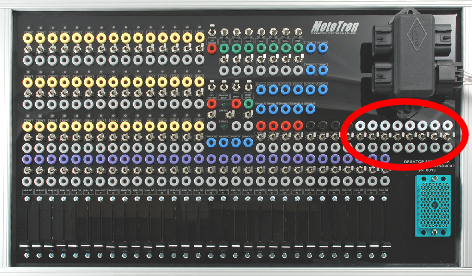

Communications

The Simulator supports connecting up to three CAN channels, and a RS-485 channel. The jacks are located at the right side of the Simulator just below the Junction box and above the harness connector. Each connection includes an OFF/ON switch to disable/enable the channel connection.

Output Sections

These outputs connect to your ECM output pins, by designation, and in order of resource number. Refer to the datasheet for your particular ECM for resources available. Depending on the resources of the particular ECM in use, some of the Simulator output jacks may not be in use.

- LEDs: The LEDs above the outputs show status; LEDs turn on green if a Low Side Output is active and set up as “low-side,” for example, and show red if the output is active as “high-side.”

- ON/OFF: You can turn the output on/off via the switch. When off, the yellow (top) jack is inactive; the monitor (gray) jack is usable with the switch in either the ON or OFF position.

- Output jacks: The top jack (yellow) of each output directly connects to the respective ECM output resource. Output characteristics of the respective ECM resource are thus conveyed.

The lower (gray) jacks are the respective voltage-level monitors only.

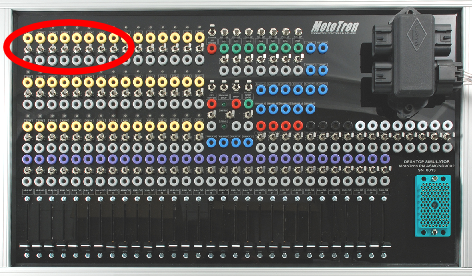

Low Side Outputs

Labeled LSO1-LSO8, eight Low Side Outputs are located in the upper left corner of the Simulator.

INJ Outputs

Labeled INJ1-INJ12, twelve fuel injector Outputs are located at the left side of the Simulator.

EST Outputs

Labeled EST1-EST16, the 16 electronic spark timing Outputs are located at the left side of the Simulator. Note: In order to see EST firing indications, turn the respective EST LED ON/OFF switch to OFF.

H-Bridge Outputs

Labeled H1+, H1-, H2+, H2-, and H3+, H3-, the six H-bridge connections are located at the top center of the Simulator.

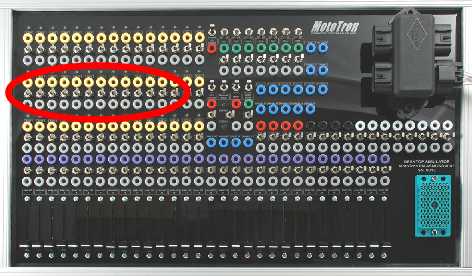

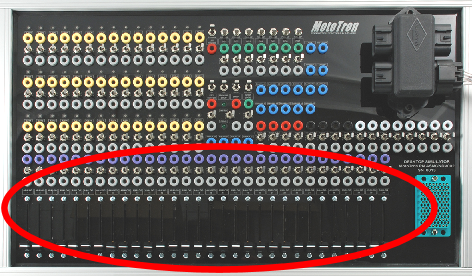

Analog/Digital Input Sections

Analog Inputs

Labeled Analog 1-Analog 30, the Analog Inputs (switchable - On / Off) are located along the bottom of the simulator, together with dedicated potentiometer sliders, 0-5V. Note: To connect your own sensor, use the gray jack, and switch the corresponding ON/OFF switch to OFF.