ECM-S12-24

ECM-S12-24

-

ECM-S12-24

Product Summary

These rugged embedded controllers are capable of operating in harsh automotive, marine and off-highway applications. Hundreds of successful industrial applications prove the capability of this module. Based on a proven microprocessor, it is capable of delivering complex control strategies. The CAN 2.0B datalink ensures interoperability with other system components.

- Features include:

- Freescale MC9S12DT128, 24MHz Microprocessor

- Operating Voltage: 8-20VDC

- Operating temperature ranging between -40°C to 105°C

- Sealed connectors operable to 10 ft submerged

- Family includes:

- ECM-S12-24-0801

- ECM-S12-24-0802

- ECM-S12-24-0803

- ECM-S12-24-0804

Datasheets

ECM-0S12-024-0801 & ECM-0S12-024-0804

ECM-0S12-024-0802

Frequently Asked Questions (FAQ)

Current Draw on the 24-Pin Family

Power draw should be the base below, plus power required for sensor inputs (from XDRP) and driven loads.

- SECM08xx(ECM PROD): approx. 100mA at 13.8V (key on, module-only, no external loads or sensors).

- SECM08xx (ECM DEV) : approx. 270mA at 13.8V (key on, module-only, no external loads or sensors).

- MCHI04xx (GCM PROD): approx. 100mA at 13.8V (key on, module-only, no external loads or sensors).

- MCHI04xx (GCM DEV) : Does not exist.

The above numbers are from a quick test here on-bench for the various modules, with a baseline "empty" application and with nothing but power, ground and CAN connections. The SECM08xx (ECM DEV) draws additional current to drive the additional calibratable memory circuitry. This data comes from one SECM 24-pin DEV module.

For the MCHI04xx (GCM) family, the key-off fully-shutdown power draw on BATT should be less than 0.5mA.

Difference Between ECM0502 and GCM0402

When the controllers shut down, there is a difference in the way calibrations are stored. ECM does not have separate key-switch and battery pins so there is no way the controller would know to save the calibrations before a shutdown. In this case, it would have to save these values periodically; whereas, in the case of a GCM, there are two separate key-switch and battery pins so the module can save Non-Volatile data when a shutdown is commanded and then go to sleep.

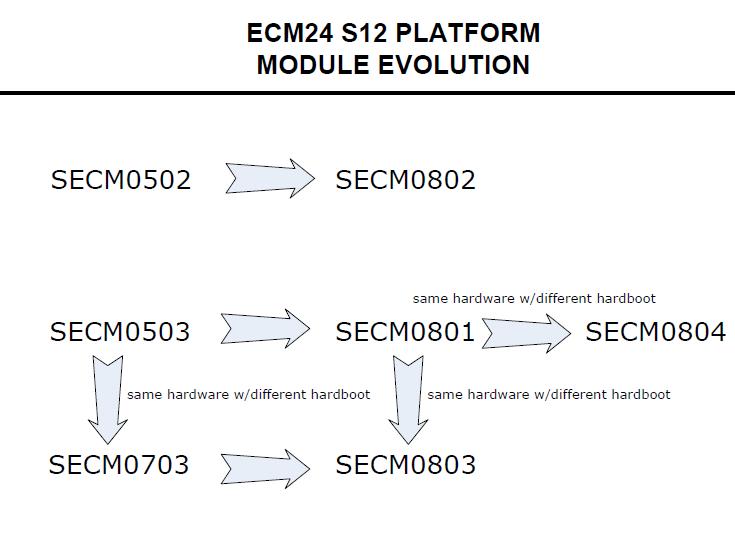

ECM/GCM-S12-24 Part Number Changes

- The SECM0502 is obsolete, replaced by SECM0802. These modules are functionally equivalent.

- The SECM0503 is obsolete, replaced by SECM0801. These modules are functionally equivalent.

- The SECM0804 is a "made" part, created from an SECM0801 with a different general-purpose hardboot loader.

- The SECM0703 is obsolete, replaced by SECM0803.

- The SECM0703 is a "made" part, created from an SECM0503 module with a customer-specific hardboot loader.

- Likewise, the SECM0803 is a "made" part, created from an SECM0801 module with that same customer-specific hardboot loader.

Notes on the ECM-S12-24 Part Number Migration

There are different software hardboots installed on the devices, but the physical hardware is identical.

SECM0801 (SECM0503) "HB V1P2" hardboot CityID 129 = 0x81

SECM0804 "HB_4_3_RC1_PROD" hardboot CityID 11 = 0x0b

I am unfamiliar with differences between these two hardboot versions, except for the hardboot CityID.

The reason for the OEM part number changes, e.g. from SECM0503 to SECM0801, is typically due to changing internal components (replacing a transistor that is end-of-life with a new, equivalent, transistor) or similar issue. However, externally-visible functionality is expected to be the same: same ADC pull-up values, etc.

Thus, the inputs/outputs are the same for SECM0503 / SECM0801 and SECM0804.

We have Woodward part numbers for all products, but please work with the quote team to make sure you get what you need. Of course, the tech support team can help, as required.

Difference between ECM0801 and ECM0802

The 0801 is a variation of the 0802 with different pull up/pull down combinations for the analog ins and three EST's replaced by more analog ins.

CAN bus limitations

The S12 modules do not support 1000kbaud CAN bus speeds; they are hardware limited.

VR signal limits

The VR input maximium is 400v pp.

VR circuit

The VR circuit is built upon the LM1815M integrated circuit. http://www.ti.com/lit/ds/symlink/lm1815.pdf.

Working with the S12 MotoHawk Application Document

Registered wiki users can download the "Working with the S12" application help. Understanding this document is imperative for using the S12 based MotoHawk modules. http://www.neweagle.net/support/wiki/index.php?title=MotoHawk_Resource_Documents

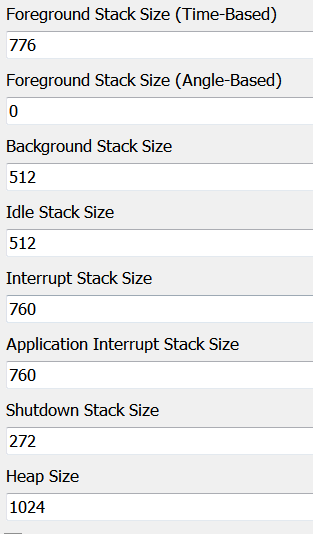

S12(X) Recommended Stack Size

The "Working with the S12" Application Document indicates a stack baseline when starting your application. Below is another recommended stack size if the stack baseline is low in certain areas.

NOTE: The following stack sizes are recommendations and should be adjusted according to the application requirements.

Other Engine Control Modules

More Information: Engine Control Modules