Hybrid Truck System

__NOTITLE__

Opportunity

- Provide the electronic controls, control algorithm and system integration for an aftermarket electric vehicle / Hybrid electric vehicle (EV/HEV) system for a class 8 vehicle (greater than 33,000 pounds).

- System operates in electric vehicle mode when in port to provide zero emissions while queuing and operates in hybrid electric vehicle mode during normal operation to provide better fuel economy.

- Integrate the system on a vehicle to provide prototype demonstration of the benefits.

- Support vehicle performance testing.

Solution

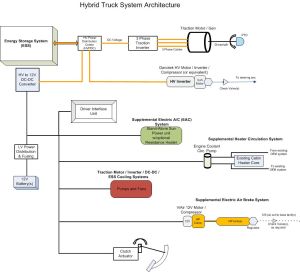

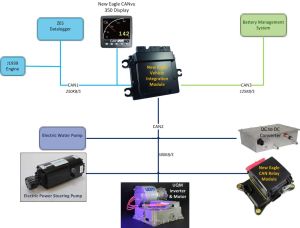

New Eagle provided the vehicle integration module, the controller area network (CAN) relay box and the vehicle integration module algorithm and software for an aftermarket EV/HEV system. We also provided extensive onsite vehicle support and system integration and verification.

Hardware

New Eagle selected the ECM-5554-112-0904 calibratable electronic control module for the vehicle integration module (VIM) and the Multiplexed Power Distribution Module (MPDM) for the CAN relay controller. The VIM interfaces with all of the components in the system

Toolchain

Control Algorithm

Results

- Provides electric vehicle (EV) operation while in port for up to 10 hours and at speeds up to 20mph.

- Runs in hybrid electric vehicle mode through the PTO during normal operation.

- Improves fuel economy by up to 25%.

- Charges through the engine and regenerative braking.

- Provides high voltage operation from 403 volts to 550 volts.

- Implements a J1939 compatible CAN 2.0 link.

- 1-1½ year return on investment in fuel savings.