Cascadia Motion (Rinehart Motion)

Product Summary

The Cascadia Motion Systems (RMS) AC Traction Controllers are designed for on-road and off-road Electric (EV) or Hybrid Electric (HEV) applications.

The PM-Series and RM-Series families are typically the lightest and smallest inverters for their power due to their high heat flux thermal design approach. The company has extensive experience in automotive, commercial vehicles, motorsports and military vehicle traction applications.

Datasheets

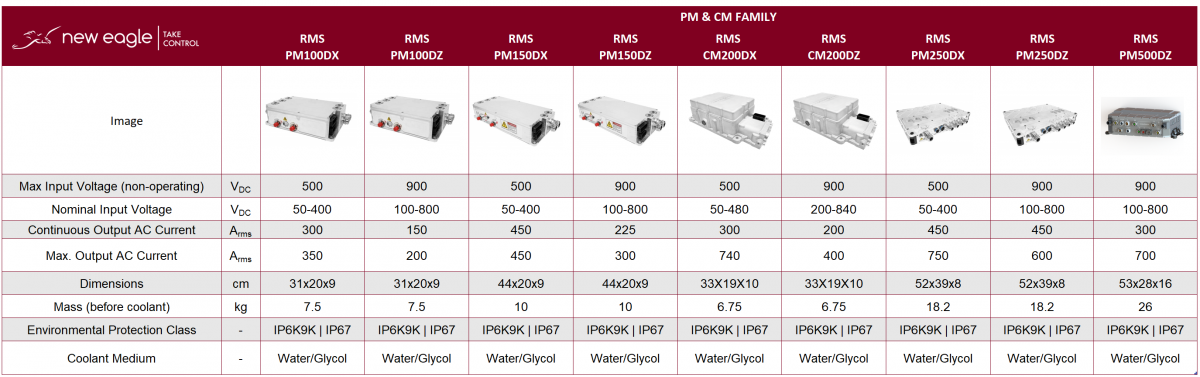

PM Family of Inverters

RMS-PM-100

RMS-PM-150

RMS-PM-250

RMS-PM-500

CM Family of Inverters

RMS-CM-200

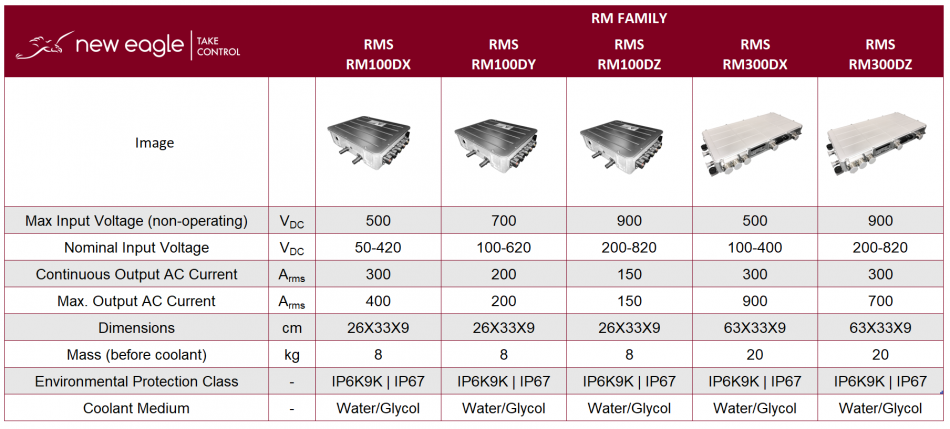

RM Family of Inverters

RMS-RM-100

RMS-RM-300

Documentation

Software Release Notes

Please click here to view the latest RMS software release notes.

In the RMS software release notes, you can find the Cascadia Motion documentation.

Documentation includes:

- RMS PM Hardware User Manual

- RMS PM Software User Manual

- RMS CAN Protocol

- PM100 HV Connection Manual

- Much more

Additional documentation

How to Set Up an RMS Inverter

Here is an excellent guide to getting started with an RMS inverter.

Cascadia releases firmware updates often.

A set-up GUI must be installed and connected to a PC serial port.

Reinhart offers integration documentation for many popular motors.

Installation for Use with a Remy Motor

Step-by-step instructions to installing a Cascadia Motion inverter for use with a Remy motor. This document describes the multiple types of Remy motors and the process to set up the motor type.

Both the PM100 and PM150 series inverters use AN6 coolant fittings.

CAN Interface for RMS

MotoHawk CAN Library for RMS PM100

MotoHawk CAN Library for RMS PM100

The MotoHawk library supports RMS release BB2_20111109_14C0.hex. Request more information on the library at sales@neweagle.net. This library and the RMS PM family of inverters integrate well with the New Eagle EV Supervisory Control system and furthermore make a nice EV powertrain combination with one of the supported motors.

CAN Configuration Parameters

New Eagle's Application Engineering team can assist on a consulting or applications contract in the correct settings of the EEPROM setting for successful implementation of the RMS drive. Many of the off-the-shelf settings are made to assist users who directly connect the pedal/brake interface to the inverter.

A more sophisticated (and safer) strategy for EVs is to use a supervisory controller with control over CAN. This is one of the functions of the New Eagle EV Supervisory controller.

Please contact sales for more information on our EEPROM settings file.

Electric Motors Supported by the RMS Traction Inverter

- Siemens/Ford Ranger Induction Motor

- Remy HVH250

- Remy HVH410

- MES-DEA 200-250 Induction Motor

- EVO AF-140 4T

- EVO AF-140 3T

- EVO AF-130 3T

- EVO AF-230 6T/AF-130 6T

- EVO AF-130 3T 5x Resolver

- EVO AF-130 6T 5x Resolver

- EVO AF-130 5T

- EVO AF‐140 4T 1/2 Stack

- Yasa 750 PM Motor

- Siemens 1PV5135-4WS28

- Parker PM Motor

- Remy HVH250HT Motor (In Development)

- EVO AF-140-12 PM Motor

- MES Induction Motor

- UQM-75 Motor

- EMRAX PM Motor

- Yasa 400 PM Motor with sin/cos encoder

- Remy HVH410‐150S

- Numerous customer-specific proprietary installations

Frequently Asked Questions (FAQ)

Q: What is the approximate weight of the unit?

A: The PM100DX weighs approximately 19 lbs or 8.62 kg.

Q: What is the switching frequency on the PM100?

A: The switching frequency is 12 kHz.

Q: Can I run the PM100DX over voltage?

A: The PM100DX family has a hardware over-voltage detect threshold at 420V +/-5V. The 360V nominal rating is for the purpose of statistical tolerance against single-event burnout of IGBTs when there is a large population of units in the field.

What are the differences between the DX and DXR?

A: The only physical difference between the DX and DXR is a higher value current sensor, there are no other physical differences.

From the Manufacturer:

The PM100DX family has a hardware over-voltage detect threshold at 420V +/-5V or so. This is a non-maskable hardware limit, not a parameter, and you can’t change it.

The 360V nominal rating is for the purpose of statistical tolerance against single-event burnout of IGBTs when there is a large population of units in the field. This is a shortcoming of Silicon IGBTs and affects the FIT rate, but at very low numbers. You need to have less than 50% of the breakdown voltage across an IGBT when it is struck by a cosmic ray or it can fail by forming a conducting channel where the particle went through the Silicon chip and the follow-on current will melt the Si in that local area. An Infineon 650V IGBT3 has actual breakdown at 720V +/-5V, hence the 50% of 720 = 360V.

The drive will operate at full rating up to 420VDC without technical issues, but the over-volt fault detector is pretty fast so typical noise and ripple on the DC Link means you can’t go above 405V or a tad higher without getting occasional “nuisance” fault trips.

Also note that after half a mile the battery voltage will drop to the nominal plateau, and under any kind of load it will droop. There may be some issues tuning the DC Bus regen override feature to avoid nuisance over-voltage faults as there isn’t much headroom left – but I think this is solvable.

The only physical difference DX –> DXR is a higher value current sensor, there are no other physical differences.