Raptor Rapid Control Prototyping

Take control of your system development from the start without paying the high cost typical for most rapid control prototyping hardware. Our embedded Model-Based Development (eMBD) platform, Raptor, provides the speed and flexibility of traditional rapid control prototyping using the MATLAB/Simulink environment, but uses hardware that costs a small fraction of similar systems.

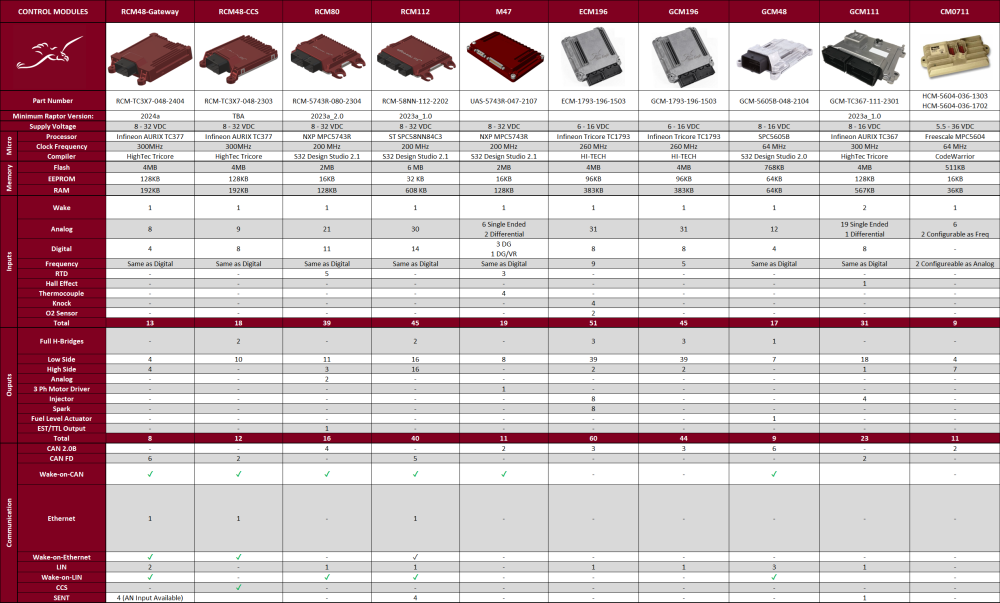

The Raptor Toolchain is a suite of software tools matched with off-the-shelf controller products designed to assist businesses as they develop control software for complex electromechanical systems. Developers can easily create, compile, build and flash the model onto ruggedized, off-the-shelf hardware without the hassle of manual programming. In addition, each Raptor-enabled ECU ranges in pin count, I/O capabilities and processor configuration to better suit a variety of applications while costing significantly less than typical prototyping hardware.

With fast development iterations using model-based simulation, rapid prototyping, controls development and ruggedized, off-the-shelf hardware, developers can optimize their control system design in a cost-efficient manner.

Rapid Prototype Development

Get your prototype up and running quickly with the Raptor tool suite. Utilizing the graphical programming environment of MATLAB/Simulink, developers can quickly and easily develop software using multiple block libraries with numerous interface functionalities and configurable I/O capabilities. Our tools allow you to automatically build, test and integrate prototype models, as well as make real-time calibration changes, without manual programming.

- Run MATLAB/Simulink models on open ECU hardware in minutes using this intuitive software environment to rapidly develop control strategies.

- Automatically compile, build and flash the control model diagram without manual programming.

High Quality Controllers

Automatically integrate your controls software onto rugged, cost-efficient hardware built to endure the harshest of environments. New Eagle offers a variety of trusted ECUs that are tailored to suit a variety of applications and range in pin count, input, output, memory and processor configuration. With our ASIL capable, IP6k9k compliant controllers that can typically operate in temperatures ranging from -40°C to +105°C, our ECUs are built with the most rigid standards available.

In general, we have the following categories for controllers:

- Body Control Modules (BCMs)

- Engine Control Modules (ECMs)

- Raptor Control Modules (RCMs)

- General Control Modules (GCMs)

- Hydraulic Control Modules (HCMs)

- Telematics Control Modules (TCMs)

Although a controller may have a function listed, such as Body Control Module (BCM), it is able to be used in other functions. Typically, the controller for a particular application is selected based on hardware capability such as I/O need, processor capability, communication requirements and voltage operating range.

High Quality Displays

Raptor also targets embedded displays with the same embedded Model-Based Development tools.

- PC-based simulation of applications created during Simulink build

- Exposes user input (buttons) via standard trigger mechanism

- Automated bitmap code generation

Scalable Solution

With our Raptor-enabled ECUs and tools, engineers will save money and time throughout the development cycle. Not only can these ECUs be used during the initial prototyping stages, but these controllers are also scalable and intended for volume production. Utilize the same hardware and tools throughout the entire system lifecycle and avoid extra iteration cycles that are normally required for production hardware.