ECM-S12X-070

ECM-S12X-070

Product Summary

A new Engine Control Module in the MotoHawk modules product line, these rugged controllers are capable of operating in harsh automotive, marine, and off-highway applications. Numerous marine applications have proven the capability of this family. Based on the Freescale MC9S12 family of microprocessors, the ECM-S12X-070-1001 is capable of delivering complex control strategies. The onboard floating-point unit and high clock frequency allow software to be executed in shorter times. The CAN 2.0B datalink ensures interoperability with other vehicle systems.

- Features include:

- Freescale MC9S12XET256, 50 MHz Microprocessor

- Operating Voltage: 6.5-16 V, 24V (Jump start), 5V (crank)

- Operating Temperature: -40deg C to +85deg C (105deg C in some applications)

Datasheets

LSD Information

- Only LSO1 has current sensing. The current monitoring on LSO1 is intended for diagnostic purposes, or to indicate high vs. low motor load. The Vad=.255*lout, and is 10-bit.

- PWM is supported in MotoHawk on LSO1, 2, 3, 4, 5, 6, 7, and 8. However, only LSO 2, 3, and 4 have a flyback diode and are intended to be used as PWM. They are intended to be used as a discrete output, unless the load has no stored energy.

- For the LSO1 is capable capable of PWM, however the flyback diode is not sized for continuous PWM and was intended for discrete mode.

- If you look at the datasheet for LSO1 it will mention an A, B, and C pin. These are not separate LSO's, but instead all three pins are parallel outputs for LSO1 to allow for a higher current output.

- Family includes:

- ECM-S12X-070-1001

Quiescent Current

Measured quiescent current @ 12V = 131 mA, no loads

CAN bus limitations

The S12 modules do not support 1000kbaud CAN bus speeds; they are hardware limited.

Harness Drawings

ECM-S12X-070-1001 Pigtail Harness

ECM-S12X-070-1001 Programming Harness

ECM-S12X-070-1001 to Simulator Harness

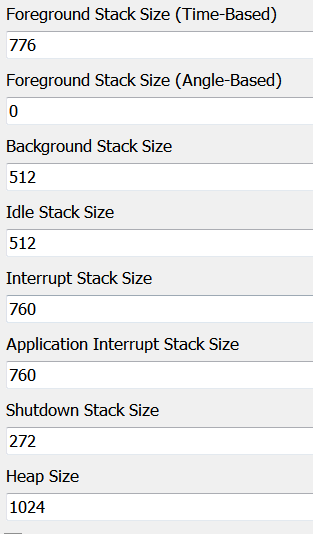

S12(X) Recommended Stack Size

The "Working with the S12" Application Document indicates a stack baseline when starting your application. Below is another recommended stack size if the stack baseline is low in certain areas.

NOTE: The following stack sizes are recommendations and should be adjusted according to the application requirements.

Troubleshooting

Out of Allocation Space

If you are getting an error message:

L1102: out of allocation space in segment PAGE_E0_SEG at address 0xE08A0C

The issue is due to the way the flash pages are written on this module. Adjusting the stack size in the target definition block will not address the issue, the stack settings in the target definition block affect the RAM allocation, the problem is related to FLASH allocation.

To correct:

- Remove any unnecessary blocks/subsystems from your model.

- Since this ECU uses paged FLASH, you may be able to restructure your model to have more top level triggers (such as multiple foreground triggered subsystems) so that your tasks can be allocated to the FLASH pages differently so as not to cause an allocation error with a particular page.

Other Engine Control Modules

More Information: Engine Control Modules