Electric Park Brake

__NOTITLE__

Opportunity

- Provide a controls solution for a motor on caliper electric park brake system on a demonstration vehicle.

- Actuate the caliper directly through an electric motor with a ball screw mechanism.

- Develop the system on a bench set up and then integrate into the vehicle using the production brake switch and CAN communications.

Solution

Hardware

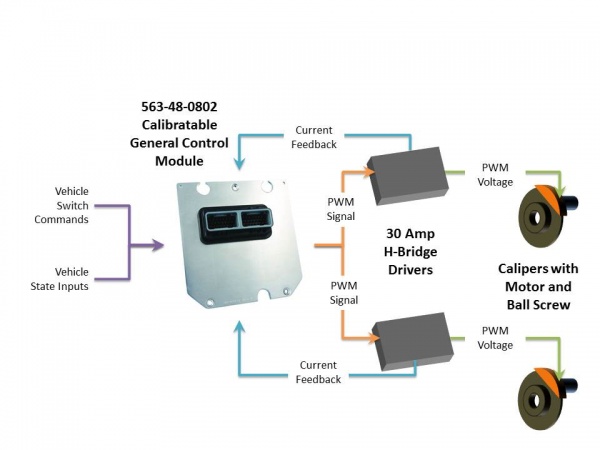

A GCM-563-48-0802 calibratable general control module was combined with two external 30 amp H-bridge drivers to provide controls and power drive circuitry for the system. The system was modeled in the Matlab / Simulink environment using a plant model of the motor on caliper system. The system was then transferred to the bench using a prototype motor on caliper unit to debug and refine the control algorithm. Finally, the control system was implemented on the vehicle integrating the CAN communications and vehicle switch interface.

Toolchain

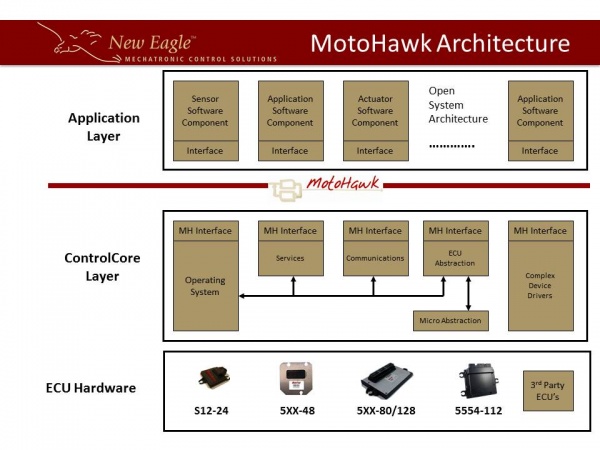

The MotoHawk and New Eagle toolchain was utilized to speed up development. Using the Matlab / Simulink environment, the team was able to unit test and integrate the model in the simulation environment in parallel to the mechanical hardware development. The early start on algorithm development saved several weeks off of the timeline. New Eagle also utilized the Network Toolbox to quickly implement the CAN messaging strategy. Since the vehicle OEM provided a DBC file of the CAN messages for the vehicle, the team quickly imported the relevant CAN messages into the CAN Receive and Send blocks within the MotoHawk model saving substantial time and allowing the team to focus on the algorithm development and vehicle refinement.

Control Algorithm

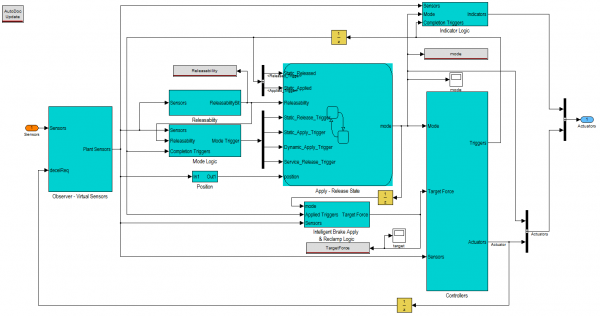

A closed loop current control of the motor with an observer was implemented. For production intent systems, sensors represent additional and sometimes unrealistic cost. New Eagle has experience estimating park brake state based on available measurements. Model based state estimation methods were used to track the park brake actuator state of relevance in order to provide state feedback to the controller. This allowed for closed loop control methods which can be tuned to optimize desired functional characteristics such as response time, or energy consumption. For the park brake system a linear state space observer was used to estimate relevant states; New Eagle can use other model based approaches for state estimation as appropriate. The control algorithm used a traditional PID feedback control law with feed forward component.

In addition to the electric park brake trigger switch a variety of vehicle conditions affected the desired electric park brake behavior. Integration with the vehicle’s network allowed for these features. Consider the following example cases and notice the subsystems in the Electric Park Brake example for ‘Releasability’, ‘Intelligent Brake Apply and Reclamp,’ and ‘Mode Logic’:

- Inhibit park brake release without service brake depression

- Inhibit park brake release during vehicle charging

- Modulate apply level based on road grade

- Automatic reapply of park brake based on vehicle speed

- Automatic apply of park brake based on charger presence

- Change apply mode based on vehicle speed

Results

By utilizing the MotoHawk and New Eagle toolchain, the team was able to demonstrate a prototype system within an extremely tight timeline. The vehicle OEM was very impressed and is interested in working further with the team as they refine the vehicle requirements.

The use of the rapid controls development platform with New Eagle's control system expertise and algorithm libraries provided a fast route to a working prototype. At the end of the project, our customer was provided with an executable specification and a documented algorithm that was generated by the Autodoc tool. In addition, New Eagle created a hardware specification for the production electronic control unit (ECU). The specification included all input and output requirements as well as control core requirements including ISO 26262 safety checks. Since the system was developed on a production automotive ECU, New Eagle was able to accurately predict the required resources.

The toolchain and the production electronic control units allowed the team to concentrate on the key aspects of the system knowing that the underlying ECU hardware and low level software had already been verified and validated on multiple applications.

Customer

Proprietary