SECM70

SECM70-15XX

Product Summary

The SECM70 control platform fits a variety of applications, including gasoline and

natural gas engines for power generation, forklifts, lift trucks, and on-highway

vehicles. The SECM70 control is programmed to meet the specific needs of the

prime mover and its driven load.

At the heart of the SECM70 control is a powerful 32-bit ST SPC563M64 microprocessor that runs Woodward’s ControlCore operating system. Application programming is accomplished via Woodward’s MotoHawk application software tool. MotoHawk is a rapid controls system development tool that allows controls engineers to quickly create controls software directly within Simulink diagrams, which run on any MotoHawk-enabled electronic control modules. Application developers work directly in the Simulink environment and with a one-step build are able to go from an application model to a file that can be programmed directly into Woodward production hardware. MotoHawk provides a high-level programming environment for users who have control systems expertise but don’t necessarily have specific embedded programming skills. Once the application program has been generated and loaded into the SECM70 control via the CAN port, the user can view variables and tune the control using an appropriate service interface tool such as Woodward's Toolkit or MotoTune. Connection to other devices, such as a diagnostic tool, is accomplished by means of other CAN ports available on the control. The desired information flow is programmed into the control via MotoTune or ToolKit.

The SECM70 control consists of a single rigid printed circuit board attached to an

aluminum housing using thermal adhesive, which is then closed and sealed with

an aluminum cover. Connections to the control are made via a single 70-pin

automotive-style sealed connector. The control can be mounted directly to the

engine or frame using vibration isolators which are available pre-installed on the

control or separately.

Hardware Features

- 70-Pin platform

- Microprocessor: ST SPC563M64, 80 MHz

- Memory: 1.5 M flash, 94 K RAM, 16 K serial EEPROM

- Operating Voltage: 8–32 Vdc, 36 V (jump start), 5.5 V (crank)

- Operating Temperature: –40 to +105 °C

Inputs

- VR or digital crank position sensor

- Digital cam position sensor

- Up to 14 analogs

- Up to 5 digital (4 switch, 1 speed)

- up to 2 switch-type oxygen sensors

- Optional wide-range oxygen sensor

- Up to 2 knock sensors

Outputs

- 6 high-impedance injector drivers (up to 4 low impedance injector drivers)

- Up to 8 electronic spark-triggers for smart injection coils

- 9 low-side drivers

- 3 lamp drivers

- 1 main power relay driver

- up to 2 H-bridge drivers

- Optional 3-phase brushless DC motor driver

- 1 sensor supply (5V)

Communications

- 2 CAN 2.0b channels

Datasheets

Controller Installation Manual

More information on the Woodward Wiki

Part Numbers

| Part Num x=Inactive |

Part w/ MTG HW |

HW Version | Features |

|---|---|---|---|

| 1751-6680 | 8923-2050 | 1452 (PROD) | Mobile Industrial |

| 1751-6649 x | 8923-2051 | 1402 (DEV) | Mobile Industrial, on-the-fly calibratable |

| 1751-6681 | 8923-2052 | 1453 (PROD) | Power Generation |

| 1751-6650 | 8923-2053 | 1403 (DEV) | Power Generation, on-the-fly calibratable |

| 1751-6682 | 8923-2002 | 1459 (PROD) | Marine |

| 1751-6756 | 8923-2475 | 1559 (PROD) | Marine (MY15 revision, use the 1459 target) |

| 1751-6784 | 8923-2577 | 1759 (PROD) | Marine (MY17 revision, use the 1459 target) |

| 1751-6653 x | 8923-1987 | 1409 (DEV) | Marine, on-the-fly calibratable |

| 1751-6755 | 8923-2474 | 1509 (DEV) | Marine, on-the-fly calibratable (MY15 revision, use the 1409 target) |

| 1751-6785 | 8923-2578 | 1709 (DEV) | Marine, on-the-fly calibratable (MY17 revision, use the 1409 target) |

| 1751-6719 | 8923-2253 | 1562 (PROD) | Mobile Industrial |

| 1751-6713 | 8923-2258 | 1512 (DEV) | Mobile Industrial, on-the-fly calibratable |

| 1751-6720 | 8923-2254 | 1563 (PROD) | Power Generation |

| 1751-6714 | 8923-2259 | 1513 (DEV) | Power Generation, on-the-fly calibratable |

| 1751-6722 | 8923-2256 | 1565 (PROD) | On-Highway |

| 1751-6716 | 8923-2261 | 1515 (DEV) | On-Highway, on-the-fly calibratable |

| 1751-6723 | 8923-2257 | 1566 (PROD) | Hydraulic |

| 1751-6717 | 8923-2262 | 1516 (DEV) | Hydraulic, on-the-fly calibrati]able |

| 1751-6767 | 8923-2583 | 1752 (PROD) | Mobile Industrial, MPC5642A |

| 1751-6772 | 8923-2584 | 1702 (DEV) | Mobile Industrial, on-the-fly calibratable using MPC5642A |

| 1751-6768 | 8923-2587 | 1753 (PROD) | Power Generation, MPC5642A |

| 1751-6773 | 8923-2588 | 1703 (DEV) | Power Generation, on-the-fly calibratable using MPC5642A |

| 1751-6769 | 8923-2581 | 1754 (PROD) | Marine, MPC5642A |

| 1751-6774 | 8923-2582 | 1704 (DEV) | Marine, on-the-fly calibratable using MPC5642A |

| 1751-6770 | 8923-2585 | 1755 (PROD) | On-Highway, MPC5642A |

| 1751-6776 | 8923-2586 | 1705 (DEV) | On-Highway, on-the-fly calibratable using MPC5642A |

| 1751-6771 | 8923-2579 | 1756 (PROD) | Hydraulic, MPC5642A |

| 1751-6777 | 8923-2580 | 1706 (DEV) | Hydraulic, on-the-fly calibratable using MPC5642A |

Related Part Numbers

| Part Number | Description |

|---|---|

| 8923-1761 | Connector Kit |

| 1635-1772 | Connector Only |

| 8996-2162 8996-2163 8996-2164 |

Crimp Tools |

| 8996-2167 | Removal Tools |

| 1635-1800 | Boot Key |

| 5404-1141 | Pig Tail |

| 5404-1364 | Development Harness |

| 5404-1341 | Desktop Simulator Harness |

Model Variant Features

| Function | MI-1402/1452 | MI-1512/1562 MI-1702/1752 |

PG-1403/1453 | PG-1513/1563 PG-1703/1753 |

SK-1409/1459 | SK-1509/1559 | SK-1704/1754 | OH-1515/1565 OH-1705/1755 |

LV-1516/1566 LV-1706/1756 |

|---|---|---|---|---|---|---|---|---|---|

| 1751-6649/6680 | 1751-6713/6719 | 1751-6650/6681 | 1751-6714/6720 | 1751-6653/6682 | 1751-6715/6721 | 1751-6774/6769 | 1751-6716/6722 | 1751-6717/6723 | |

| PIN # | |||||||||

| AN1 (221k_PD) | 28 | 28 | 28 | 28 | 28 | 28 | 28 (10k_PD) | 28 | 28 |

| AN2 (221k_PD) | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 |

| AN3 (221k_PD) | 22 | 22 | 22 | 22 | 22 | 22 | 22 | 22 | 22 |

| AN4 (221k_PD) | 42 | 42 | 42 | 42 | 42 (2.21k_PU) | 42 (2.21k_PU) | 42 (2.21k_PU) | 42 | 42 |

| AN5 (4.75k_PD) | 43 | 43 | 43 | 43 | 43 (2.21k_PU) | 43 (2.21k_PU) | 43 (2.21k_PU) | 43 | 43 (221k_PD) |

| AN6 (4.75k_PD) | 47 | 47 | - | - | 47 (2.21k_PU) | 47 (2.21k_PU) | 47 (2.21k_PU) | - | 47 (221k_PD) |

| AN7 (51.1k_PD) | 44 | 44 | 44 | 44 | 44 (1ms T ) | 44 (1ms T ) | 44 (1ms T ) | 44 | 47 (221k_PD) |

| AN8 (4.75k_PD) | 45 | 45 | 45 | 45 | 45 (51.1k_PD) | 45 (51.1k_PD) | 45 (51.1k_PD) | 45 | 45 (221k_PD) |

| AN9 (2.21k_PU) | 39 | 39 | 39 | 39 | 39 (1k_PU) | 39 | 39 | 39 | 39 |

| AN10 (2.21k_PU) | 40 | 40 | 40 | 40 | 40 (1k_PU) | 40 | 40 | 40 | 40 |

| AN11 (2.21k_PU) | 41 | 41 | 41 | 41 | 41 (1k_PU) | 41 | 41 | 41 | 41 |

| AN12 (4.75k_PU) | 59 | 59 | 59 | 59 | 59 (1k_PU) | 59 (221k_PD) | 59 (221k_PD) | 59 | 59 (51.1k_PU) |

| AN13 (4.75k_PU) | 60 | 60 | 60 | 60 | 60 (2.21k_PU) | 60 (221k_PD) | 60 (221k_PD) | 60 | 60 (51.1k_PU) |

| AN14 (10k_PU) | 61 | 61 | 61 | 61 | - | - | - | 61 | - |

| AN16 (51.1k_PD) | - | - | - | - | 46 | 46 | 46 | - | 62 (221k_PD) |

| AN17 | - | - | - | - | - | - | - | - | - |

| AN18 | - | - | - | - | - | - | - | - | 64 |

| AN19 | - | - | - | - | - | - | - | - | 63 |

| EGO1 | 65/66 | 65/66 | 65/66 | 65/66 | - | - | - | 65/66 | 65/66 |

| EGO2 | 49/50 | 49/50 | - | - | - | - | - | - | 49/50 |

| UEGO | - | - | 47(SNS), 50(SR), 3(HTR), 49(TG), 33(INRC) | 47(SNS), 50(SR), 3(HTR), 49(TG), 33(INRC) (Improved accuracy) |

- | - | - | 47(SNS), 50(SR), 3(HTR), 49(TG), 33(INRC) (Improved accuracy) |

- |

| EK1 | 63/64 | 63/64 | 63/64 | 63/64 | 63/64 | 63/64 | 63/64 | 63/64 | - |

| EK2 | 62/46 | 62/46 | 62/46 | 62/46 | - | - | - | 62/46 | - |

| SWG1 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| SWG2 | 27 | 27 | 27 | 27 | 27 | 27 | 27 | 27 | 27 |

| SWG3 | 29 | 29 | 29 | 29 | 29 | 29 | 29 | 29 | 29 |

| SWG4 / BOOT | 26 | 26 | 26 | 26 | 26 | 26 | 26 | 26 | 26 |

| CAM_DG | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| CNK_DG | 31 | 31 | 31 | 31 | 31 | 31 | 31 | 31 | 31 |

| SPD | 33 | 33 | - | - | - | - | - | - | 33 |

| CNK_VR/SPD_VR | 16/17 | 16/17 | 16/17 | 16/17 | 16/17 | 16/17 | 16/17 | 16/17 | 16/17 |

| LSO1 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 |

| LSO2 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| LSO3 (CS) | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| LSO4 | 5 | 5 (Inductive capable) | 5 | 5 (Inductive capable) | 5 | 5 | 5 | 5 (Inductive capable) | 5 |

| LSO5 | 9 | 9 (Inductive capable) | 9 | 9 (Inductive capable) | 9 | 9 | 9 | 9 (Inductive capable) | 9 |

| LSO6 (CS) | 10 (no CS) | 10 (no CS) (Inductive capable) | 10 (no CS) | 10 (no CS) (Inductive capable) | 11 (10 no CS) | 11 (10 no CS) | 11 (10 no CS) | 10 (no CS) (Inductive capable) | 11 (166mA/Volt) |

| LSO7 (CS) | 15 (no CS) | 15 (no CS) | 15 (no CS) | 15 (no CS) | 15 | 15 | 15 | 15 (no CS) | 15 (166mA/Volt) |

| LSO8 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| LSO9 | 23 | 23 | 23 | 23 | 23 | 23 | 23 | 23 | 23 |

| MPRD | 55 | 55 | 55 | 55 | 55 | 55 | 55 | 55 | 55 |

| LAMP1 | 58 | 58 (Improved diag) | 58 | 58 (Improved diag) | - | - | - | 58 (Improved diag) | 58 |

| LAMP2 | 57 | 57 (Improved diag) | 57 | 57 (Improved diag) | - | - | - | 57 (Improved diag) | 57 |

| LAMP3 | 56 | 56 (Improved diag) | 56 | 56 (Improved diag) | - | - | - | 56 (Improved diag) | 56 |

| INJ1 (PH) | 34 | 34 | - | - | - | - | - | 34 | 34 |

| INJ2 (PH) | 35 | 35 | - | - | - | - | - | 35 | 35 |

| INJ3 (PH) | 1 | 1 | - | - | - | - | - | 1 | 1 |

| INJ4 (PH) | - | - | - | - | - | - | - | 18 | - |

| INJ4 | 12 | 12 | - | - | 12 | 12 | 12 | - | 12 |

| INJ5 | 13 | 13 | - | - | 13 | 13 | 13 | - | - |

| INJ6 | 14 | 14 | - | - | 14 | 14 | 14 | - | - |

| H1 | 51/52 | 51/52 | 51/52 | 51/52 | - | - | - | 51/52 | 51/52 |

| H2 | - | - | 34/35 | 34/35 | - | - | - | - | - |

| 3-Phase | - | - | - | - | 51/34/52 | 51/34/52 | 51/34/52 | - | - |

| EST1 | 6 | 6 | 6 | 6 | - | - | - | 6 | 6 |

| EST2 | 8 | 8 | 8 | 8 | - | - | - | 8 | 8 |

| EST3 | 11 | 11 | 11 | 11 | - | - | - | 11 | - |

| EST4 | 21 | 21 | 21 | 21 | 21 | 21 | 21 | 21 | 21 |

| EST5 | 18 | 18 | 18 | 18 | 18 | 18 | 18 | 13 | 18 |

| EST6 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 14 | 19 |

| EST7 | - | - | 13 | 13 | - | - | - | - | 13 |

| EST8 | - | - | 14 | 14 | - | - | - | - | 14 |

| MotorPhaseVSense_A | - | - | - | - | 58 | 58 | 58 | - | - |

| MotorPhaseVSense_B | - | - | - | - | 57 | 57 | 57 | - | - |

| MotorPhaseVSense_C | - | - | - | - | 56 | 56 | 56 | - | - |

17xx Modules

- Available since MotoHawk 2017b Beta 2 or newer

- RAM and FLASH increase on MPC5642A processor

15xx Modules

- Available since MotoHawk 2015a SP0 or newer

- Improved diagnostic on LAMP pins

- Increased UEGO resolution and accuracy

- Increased switching speed on LSO4/5/6/7 and H2

- Allow LSO4/5/6 to drive inductive loads

Common I/O

| Function | PIN # |

|---|---|

| DRVP | 67 |

| BATT | 68 |

| DRVG | 69/70 |

| KEYSW | 38 |

| CAN1+ | 36 |

| CAN1- | 53 |

| CAN2+ | 37 |

| CAN2- | 54 |

Software Variant Features

14xx Modules

- Hardboot firmware version 2.06

- Programming not supported on CAN2

15xx Modules

- Available since MotoHawk 2015a SP0 or newer

- Improved diagnostic on LAMP pins

- Increased UEGO resolution and accuracy

- Increased switching speed on LSO4/5/6/7 and H2

- Allow LSO4/5/6 to drive inductive loads

- Modules that support UEGO expose an additional internal ADC resource for FVOUT. This provides the user an option to use a slightly higher resolution reading.

- Hardboot firmware version 2.08

- The factory installed application supports XCP communications and reflashing using CAN_2 at 500k with CRO = 0x188C0CF9 and DTO = 0x188BF90C

- Reprogramming supported on CAN2

Compiler

Green Hills version 4.2.4

Green Hills version 2015.1.6 (Since MootHawk 2017b)

GCC for PowerPC EABI-SPE version 4.6.0

Boot Key

A malfunctioning application previously loaded on the SECM70 can be recovered using the Boot Key recovery.

The BootKey signal needs to be connected to the SWG4 pin.

Bootstrap

The SECM70 can be forced to remain in the firmware bootloader by applying a bootstrap sequence. The bootstrap sequence is:

| Pin | State for Boot |

|---|---|

| AN1 | High |

| AN2 | High |

| AN3 | High |

| AN4 | |

| AN5 | |

| AN6 | |

| AN7 | |

| AN8 | |

| AN9 | Low |

| AN10 | Low |

| AN11 | Low |

Frequently Asked Questions/Topics

All Variants

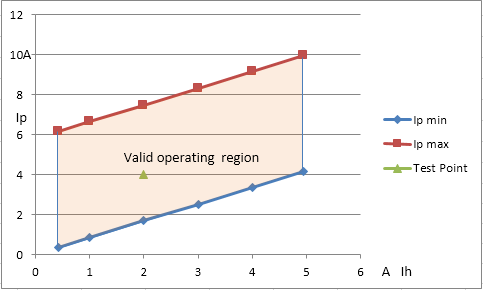

Peak and Hold Constraints

This hardware is able to programatically set the peak and hold currents of capable injector outputs. However there is an interdependency between the peak and hold and not all values are possible.

The Peak Hold Set Block also supports outputs that report the Currents that will be applied (once constrained).

Can I diagnose PWM EST outputs?

Due to the nature of the hardware, EST diagnostics are only available when driven as a sequence and not as a PWM.

The ESTs have a caveat that certain groups must not turn off at the same time as there is shared diagnostic HW.

The groupings where you should avoid turning off at the same time are:

EST 1,2

EST 3,4

EST 5,6,7,8

Why is LSO6 current sense not working?

On modules that support current sense for the resource LSO6, the load must be connected to pin 11. Pin 10 is also connected to the LSO6 driver but before the current measurement sense resistor and therefore current will not be measured.

How would you use the H1GATE_ENABLE output?

The H1GATE_ENABLE can be used to reset the ASIC responsible for driving H1 the SECM70. If H1GATE_ENABLE is not referenced in the application, then by default it will always be set in an enabled state. If a reset of the ASIC is necessary, it is suggested to set H1GATE_ENABLE to false (logic 0) for one RTI period and then return H1GATE_ENABLE to true (logic 1).

Why do I see a high current on H1 when in Fault or H1GATE_ENABLE is disabled?

Current measurement is obtained by sampling analog outputs from the ASIC. These outputs are centered at 2.5V such that +ve and -ve currents can be reported. However when in fault or disabled, the analog output channel goes to 0V and therefore is reported to have Max current.

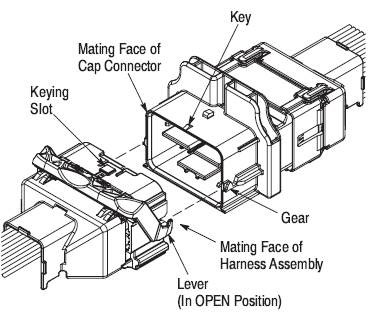

Is there an available ECU Side connector?

TE Connectivity, formerly known as Tyco Electronics Ltd, provides an inline male side mating connector which will mate to Woodward part number 1635-1772. The TE Connectivity part number is 1438726-1. More information can be found on the TE Connectivity website.

Specific Variants

Marine Specific

Is the Marine variant suited for sensorless 3-phase brushless motor?

To introduce this answer, we review that it is possible to run a 3-phase brushless DC motor with and without position sensors. A position sensor can directly indicate the position of a motor shaft. Sensorless systems are advanced enough to determine the position of the shaft through back-EMF waveforms, although complexity will increase greatly under very small signal to noise ratios (when the motor is just starting and at very slow speeds.)

Engineers have design protected for sensorless 3-phase brushless DC motor operation in SECM70, but the Marine variant is not suited for this application.

The Marine variant SECM70 should always be designed to operate a 3-phase brushless motor with hall position sensors connected to module pins 56,57,58 for PhaseC, PhaseB, PhaseA, respectively. MotoHawk Input Capture blocks can then be used with the resources MotorPhaseVSense_A, MotorPhaseVSense_B, and MotorPhaseVSense_C. The Input Capture behavior allows the application to be notified of an input pin state change, which correlates to a sample every 60 degrees. The algorithm to calculate motor position and speed is outside the scope of what MotoHawk is providing in support of this module.

How is LSO3 different than LSO6/LSO7 on the Marine variant?

LSO3 current sense is only able to measure current when the driver is in the On state. This is common to all the module variants. The Marine variant has additional current sense for LSO6 and LSO7. The current measurement at pins 11 and 15, respectively, will measure the current when the driver state is On and Off.

What is the power capability of the BLDC motor driver on the SECM70? For what type of motor was this designed?

3 phase controls a bi-directional brushless DC motor which may be used for closed-loop fluid pressure control. The motor must operate in both directions at variable speeds.

The circuit shall be capable of driving the motor at its maximum speed:

For 12V systems, no motor load (mechanical) speed is 5800RPM, stall current is 9.4A. For 24V systems, no load (mechanical) speed is 5500RPM, stall current is 7.5A.

For 12V systems, 3 phase shall support 3A continuous typical. The typical phase-phase resistance is 0.92 ohms. For 24V systems, 3 phase shall support 1.3A continuous typical. The typical phase-phase resistance is 3.2 ohms.

Resolution on A/D

MotoHawk uses 10-bit resolution on A/Ds.

Current Feedback on Hydraulic Version (1756 / 1706)

LSO6 and LSO7 pins 11 and 15 have current feedback