Raptor Platform: Difference between revisions

No edit summary |

|||

| Line 58: | Line 58: | ||

|rowspan="2" | | |rowspan="2" | | ||

|} | |} | ||

| |||

| |||

=Hardware= | =Hardware= | ||

Revision as of 19:49, 23 June 2015

New Eagle > Products Wiki > Raptor Platform

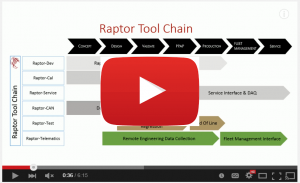

The Raptor Tool chain is a family of software products designed to guide businesses from concept to production as they develop control software for complex electromechanical systems, such as those found in hybrid or electric vehicles, mobile hydraulic systems, internal combustion engines, or other complex systems. The Raptor Tool chain consists of 6 unique software products: Raptor-Dev, Raptor-Cal, Raptor-Service, Raptor-CAN, Raptor-Test, and Raptor-Telematics. Each of these tool’s features, functionality, and workflows were designed by experienced application engineers hoping to improve upon the shortcomings of other software tools currently on the market. The Raptor Tool chain was designed to work with an extensive line of automotive-grade, production-ready control modules and displays.

Software

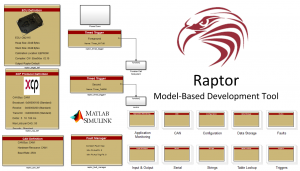

Raptor-Dev: MATLAB Simulink Development Tool

| Raptor-Dev is a library of customizable Simulink blocks that allows developers to quickly create custom software for Raptor Controllers and Raptor Displays. Developers work directly in the Simulink environment with Raptor-Dev blocks as well as native Simulink blocks and features. To learn more or access product support pages, click on the link below. |

|

Raptor-Cal: ECU Calibration Tool

| Raptor-Cal is a PC-based tool used to program (i.e. flash), calibrate, or create displays for electronic control modules. A spreadsheet-like user interface allows users to easily create displays or access all of the calibratable parameters contained in the control module. To learn more or access product support pages, click on the link below. |

|

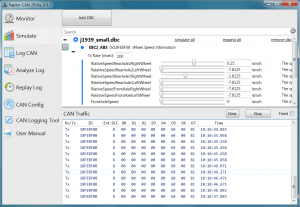

Raptor-CAN: CAN Analysis & Datalogging

| Raptor-CAN is a comprehensive, simple tool used for communicating with and monitoring CAN systems using a Kvaser or RP1210 compatible CAN adaptor. Raptor-CAN shows in-depth analysis of the CAN traffic being sent back and forth from any system, and will record this data for future reference. Raptor-CAN also has a simulate function, sending simulated CAN signals to the connected hardware (usually using a USB to CAN system) through the allotted *.dbc file. To learn more or access product support pages, click on the link below. |

|

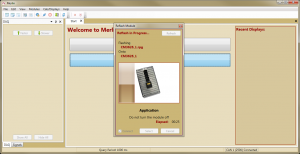

Raptor-Service: ECU Programming Tool

| Raptor-Service is a PC-based primarily intended to be used in the field for flashing software updates or troubleshooting issues using custom displays and/or data logging. Raptor-Service is essentially the same software as Raptor-Cal, but without the calibration capabilities. To learn more or access product support pages, click on the link below. |

|

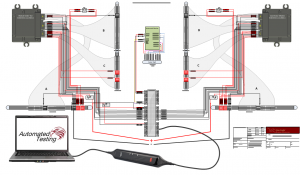

Raptor-Test: Automated Testing and Validation Tool

| Raptor-Test facilitates testing of model-based software against requirements through simulated hardware-in-the-loop (SimHIL). Raptor-Test greatly improves the effectiveness and speed of software verification and increases confidence in production intent software releases. To learn more or access product support pages, click on the link below. |

|

Raptor Libraries

| Discover the Raptor-Libraries available. To learn more, click on the link below. |

Hardware

Raptor Controllers

| New Eagle’s line of Raptor Controllers and complimentary Raptor-Dev software offer an alternative approach to the traditional programming languages: These controllers allow developers to leverage the graphical programming environment of MATLAB Simulink to quickly and easily create, edit, and debug application software. To learn more or access product support pages, click on the link below. |

|

Raptor Displays

| New Eagle’s line of Raptor Displays and complimentary Raptor-Dev software offer an alternative approach to the traditional programming languages: These displays allow developers to leverage the graphical programming environment of MATLAB Simulink to quickly and easily create, edit, and debug display software. All Raptor displays are capable of interfacing with any CAN-based actuators or sensors. And the Raptor VeeCAN 800 and VeeCAN 320 in particular have a number of analog and frequency inputs and digital outputs, which make these displays ideal all-in-one display/controller solutions for a wide variety of applications. To learn more or access product support pages, click on the link below. |

|

Raptor Dataloggers

| Raptor Dataloggers are provide the capability for event data recording and vehicle / system monitoring. These loggers use a USB 2.0 stick for data storage and effortless data retrieval. Two CAN channels are provided, preconfigured to 250K and 500k, with logging at rates up to 1ms to make this device is an ideal choice for most CAN bus environments. To learn more or access product support pages, click on the link below. |

|

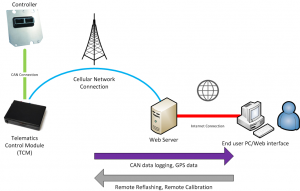

Raptor Telematics

| New Eagle has developed a Raptor™ compatible Telematics platform, which enables remote tracking and management of assets through GPS and cellular data technology. This system serves as gateway for remote administration of vehicles and data analysis. The New Eagle telematics platform can monitor and analyze driver behavior, measure fuel consumption, and detect maintenance issues with vehicles before they become a problem. The seamless integration between the New Eagle Telematics Control Module (TCM) and New Eagle ECUs also allows the option for remote calibration, reflashing of the ECU, and fault reporting.

New Eagle delivers a complete telematics solution including hardware, software, cellular plan, web server, and web portal interface. To learn more or access product support pages, click on the link below. |

|

Training

| Raptor Training, led by our team of experienced system engineers, provides hands-on experience which enables the new practitioner to gain familiarity with the Raptor tool chain by building, deploying, calibrating, and refining a real world control application. The training is an intensive three-day course that introduce users to Raptor ECU Based Rapid Prototyping and general Model-Based Controls Engineering. To learn more or access product support pages, click on the link below. |

|